Page 18 of 23

Re: 1970 Gladiator 1 Ton 6BT 12V Cummins Build

Posted: Sun Apr 28, 2013 7:06 am

by Resbum

twisted frame wrote:... I'm wondering why you might not have wanted buckets to give you the room you need for the shifters? Is it just a preference that a pickup should have a bench?...

Just looking at the trans tunnel from this angle makes it look like there's not much room for the skinny pedal but it's probably just the camera angle, right?

If this was going to be an around town, occasional 4-wheelin' truck I probably would have gone with bucket seats.

Here is the number one reason I went with a bench seat. He would have been seriously pissed only having the space of a bucket seat. There's no way to lay down:lol:

Seriously, because I plan on living out in the back of nowhere I thought it was better to have a seat that could handle three people, four in an emergency. The bench seat is just more utilitarian, and that's how I've tried to build the whole truck. I'm also kicking around ideas for a fold down back, with a storage compartment in it, when I widen it.

As for the skinny pedal. Nope, you have a good eye. It's not as tight as the picture looks, but it's close. For my size 11 foot fit's comfortably good, but someone with big ol' size 13's would find it a just doable squeeze. I left foot brake, so it wouldn't bother me at all. I'm most likely going to take about a half inch off the inside of the brake pedal and that will make it better.

Re: 1970 Gladiator 1 Ton 6BT 12V Cummins Build

Posted: Sun Apr 28, 2013 7:26 am

by Resbum

Mudbull wrote:... Ill be curious to see your seat rebuild... I like the center console on my bench seat, it can fit 8.5x11 folders, books, etc...but can fold up out of the way too.

How are you planning on covering the seats, take them to someone local? Im going back and forth between finding a set from a half ton or something that wont need to be altered, or cut the rams up and spend the money on reupholstery.

When I widen the seat I'm kicking around some ideas for having a fold down back to double as an armrest with storage in it. It might also be a double fold down so each side has it's own 9" wide armrest. Granted, the two storage areas would only be half the size of one large one. Plus, having a fold down center section makes it easier to reach in the back if you need to get something while driving. I'm also considering a compartment in the seat portion that can be accessed be lifting up the center of the seat.

Covering the seat. You and I are in the exact same boat. I've been waffling around with what I'm going to do since the day I bought the seat. I honestly don't know which route I'm going to go at the moment.

Re: 1970 Gladiator 1 Ton 6BT 12V Cummins Build

Posted: Sun Apr 28, 2013 10:52 am

by Cecil14

For the column I might suggest something just a hair newer out of a comparable GM. That will net you an on the column brights switch as well as possibly cruise controls if you find the right one. From everything I've heard a lot of the later 80s GMs (full size blazers, etc.) and XJ cherokees shared an almost identical column. Should be able to get one fairly cheap.

Just a thought I wanted to throw out there.

aa

Re: 1970 Gladiator 1 Ton 6BT 12V Cummins Build

Posted: Sun Apr 28, 2013 11:22 am

by Mudbull

Resbum wrote:

Covering the seat. You and I are in the exact same boat. I've been waffling around with what I'm going to do since the day I bought the seat. I honestly don't know which route I'm going to go at the moment.

Im leaning towards getting an aftermarket seat cover (made out of wetsuit material) and pay a local shop to cut the seams and bring it in the req'd amount, (for me) thats the best option, it may be for you too if you can find a swatch of material to have inserted.

Re: 1970 Gladiator 1 Ton 6BT 12V Cummins Build

Posted: Tue May 07, 2013 5:35 pm

by Resbum

Re: 1970 Gladiator 1 Ton 6BT 12V Cummins Build

Posted: Tue May 07, 2013 5:37 pm

by Resbum

Re: 1970 Gladiator 1 Ton 6BT 12V Cummins Build

Posted: Tue May 07, 2013 6:38 pm

by Stuka

So you pushed the wheel in closer to the dash?

Sent from my iPhone using Tapatalk

Re: 1970 Gladiator 1 Ton 6BT 12V Cummins Build

Posted: Tue May 07, 2013 7:22 pm

by Resbum

Stuka wrote:So you pushed the wheel in closer to the dash?

Only about one inch. The other three inches moved the end of the column closer to the firewall.

Re: 1970 Gladiator 1 Ton 6BT 12V Cummins Build

Posted: Tue May 07, 2013 8:59 pm

by Stuka

Ahh ok. Would be nice for extra leg room. My only complaint about my J10. Although tilt wheel would fix that.

Re: 1970 Gladiator 1 Ton 6BT 12V Cummins Build

Posted: Thu May 09, 2013 5:09 pm

by Resbum

.

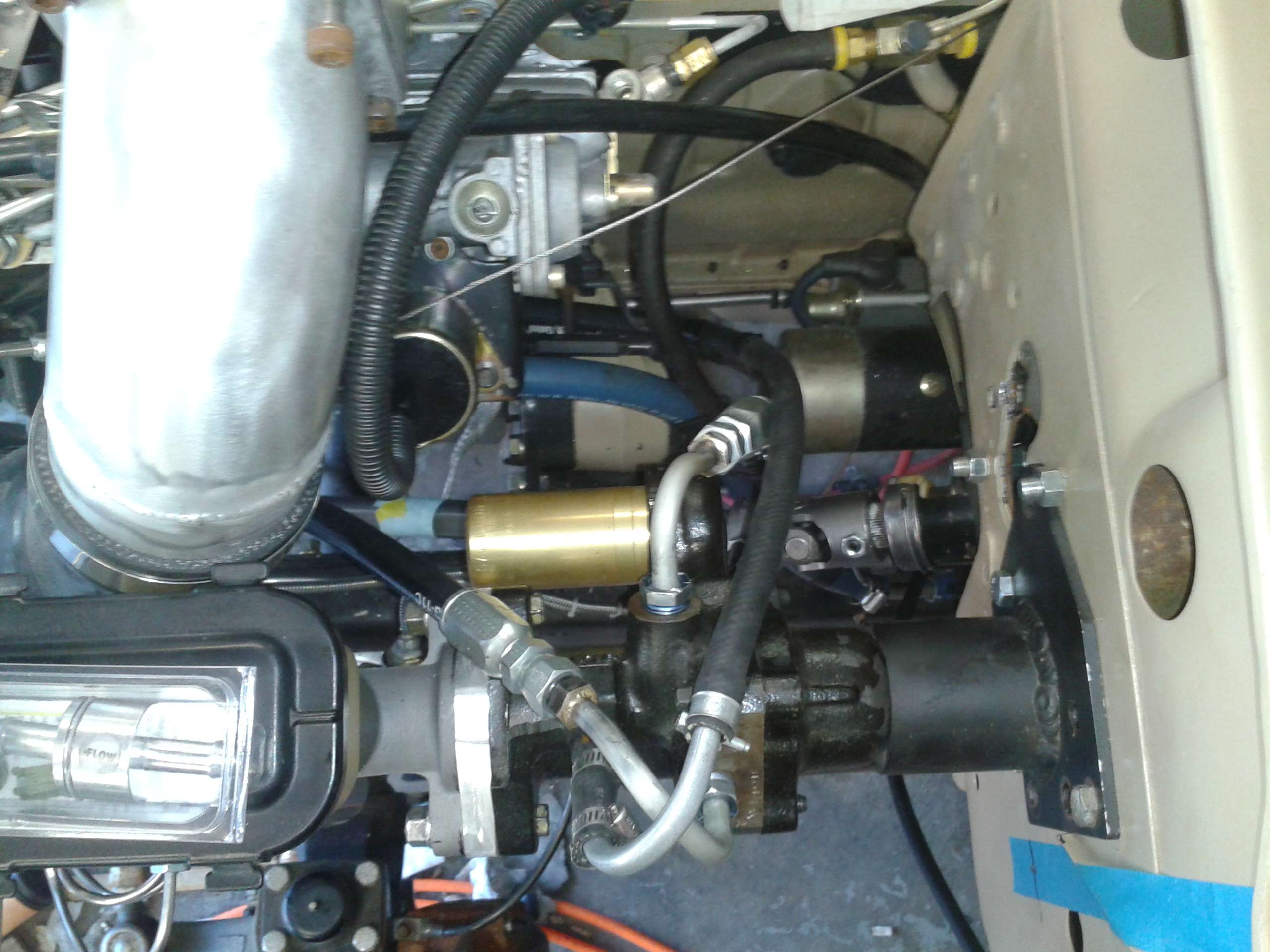

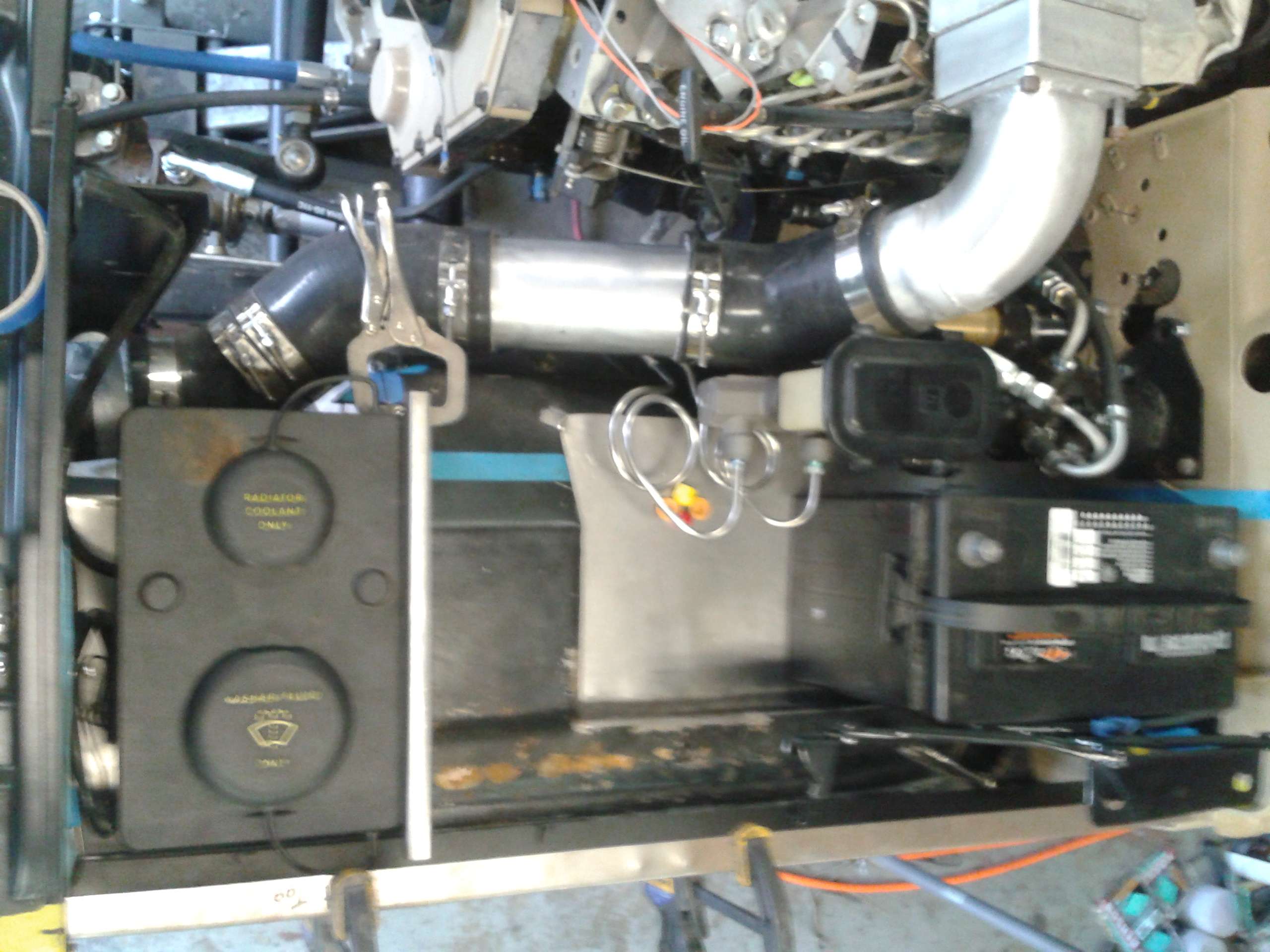

Today was a big stress relief day. I got the drivers side battery shelf and and battery test fit. All the measurements said it would fit, but until I actually saw it I was concerned about clearances. That's the last major component that needed to fit on the drivers side of the engine compartment. The passenger side battery has a mess load of room and will be a cake walk to put in. The shelf is made with 16 gauge sheetmetal.

By lowering the inner fender that 3" earlier I only had to drop the tray 2" into the inner wheelwell.

The right side of the blue tape on the firewall is where the edge of the battery will finally be. Right now there's still a piece of the inner fender that needs to be bent down. You can see it hitting the bottom right side of the battery.

The battery ended up being surprisingly easy to lift up into place.

The plan is to have the outboard battery tiedown mount to the hood hinge assembly. I'm going to tie the hinge assembly to the three inch spacer that lowered the inner fender. That should stop all lateral movement and keep the battery from shifting into the hydroboost.

Re: 1970 Gladiator 1 Ton 6BT 12V Cummins Build

Posted: Sat May 11, 2013 5:31 pm

by Resbum

Re: 1970 Gladiator 1 Ton 6BT 12V Cummins Build

Posted: Sat May 11, 2013 5:46 pm

by Resbum

.

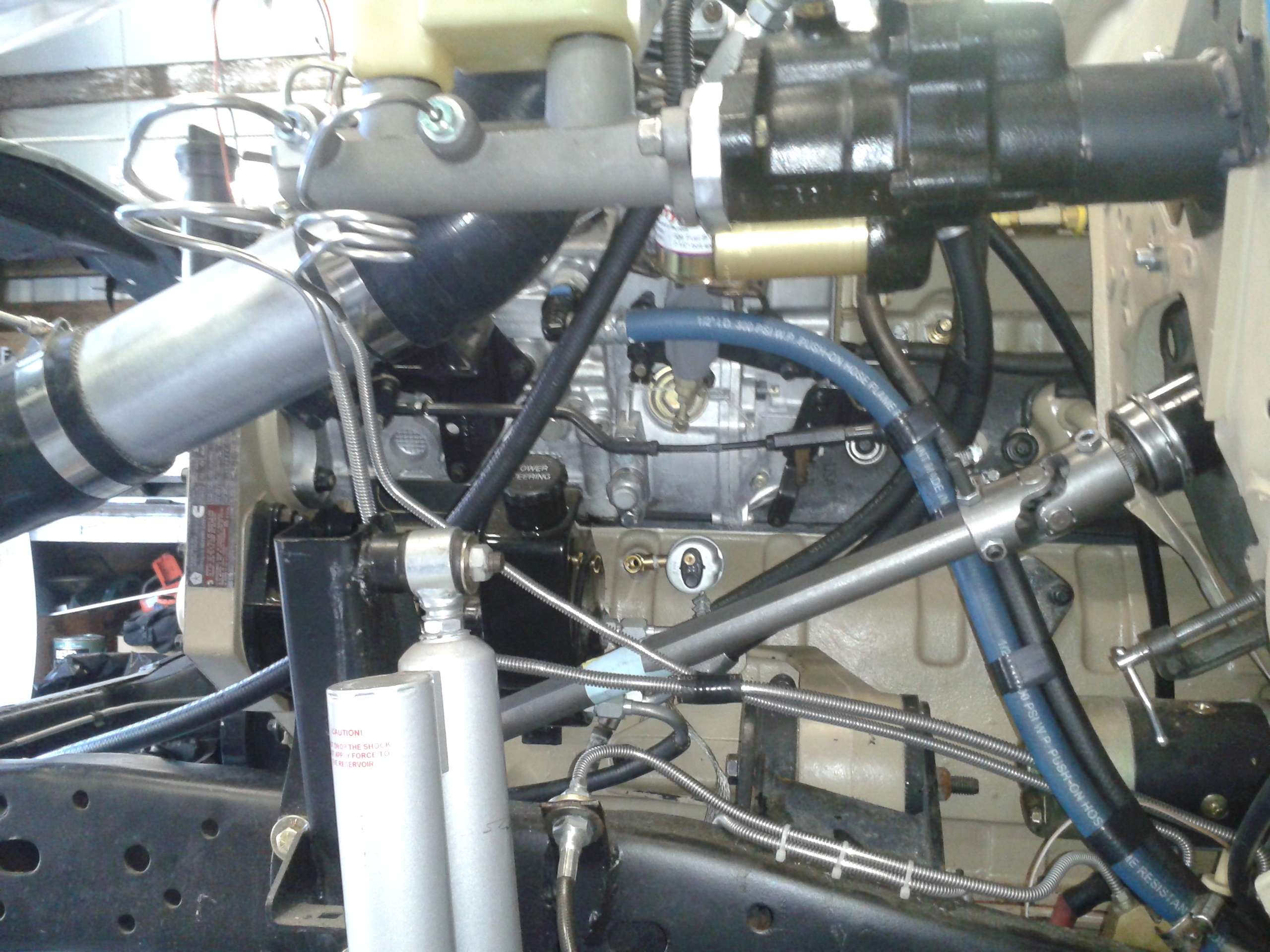

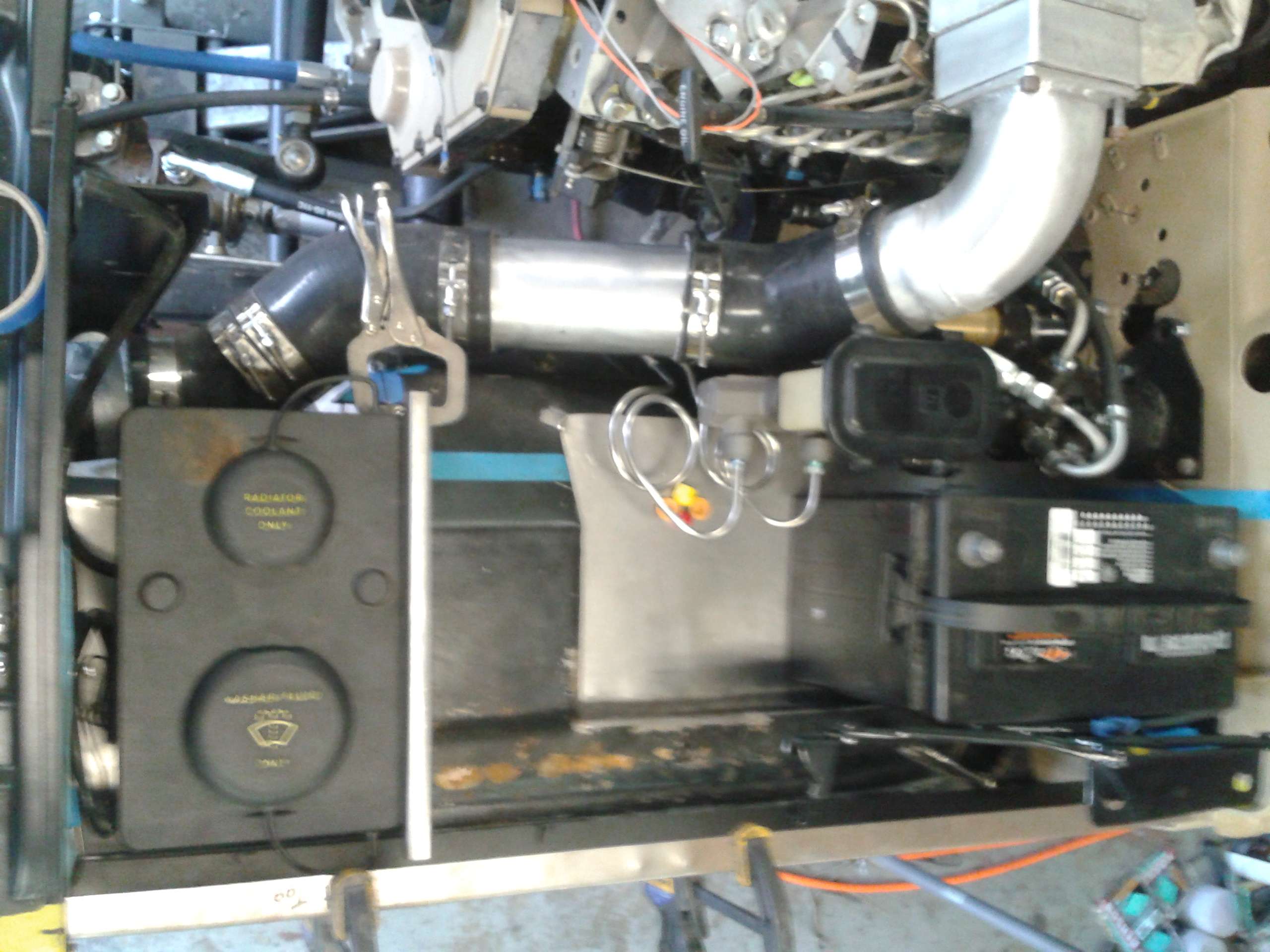

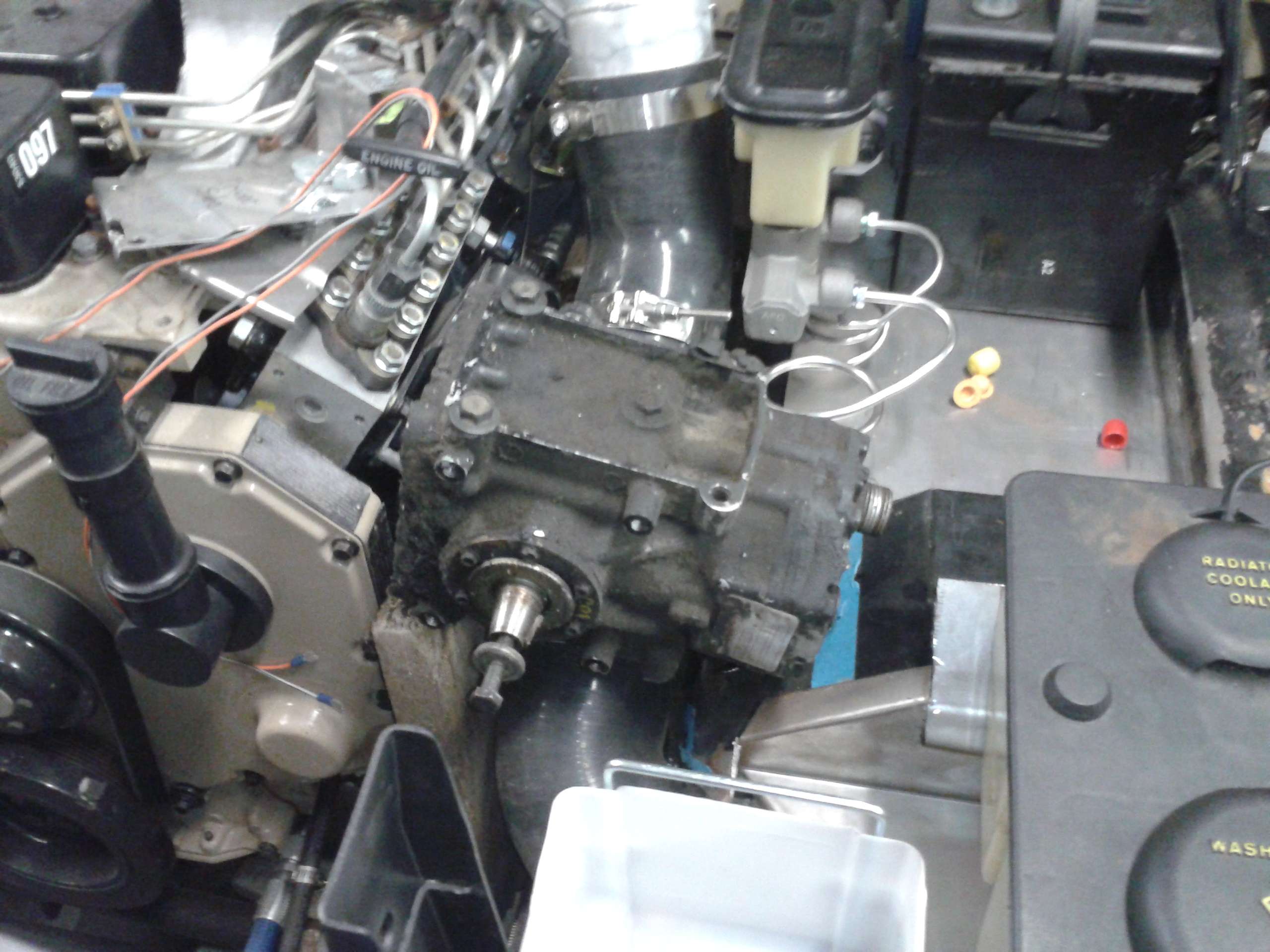

Once I had that done it was time to test fit the whole inner fender assembly and all the mechanicals that will be mounted on the drivers side of the engine compartment. I'm relieved to have the drivers side done. It was by far going to be a lot more crowded than the passenger side.

I've also been thinking about what to do along the bottom of the inner fenders to add more protection to keep things from hitting the frame rails, brake and fuel lines, intercooler piping, and keep dirt and water from coming off the tires and getting in the engine compartment.

Luckily, yesterday I was driving down the freeway and went past this tire that some dumb @$$ was kind enough to drive on until the sidewall completely shredded off the tread portion. I went back and got it. Once at the shop I cut it so it laid out flat. It's just long enough to do both side. I'll mount it to the bottom of the inner fender and it should add protection clear down to the bottom off the frame rail.

This is the side I'll have towards the tire.

Re: 1970 Gladiator 1 Ton 6BT 12V Cummins Build

Posted: Mon May 13, 2013 6:22 am

by ross80truck

Looking really nice. It is nice to see you are not rushing any of the final details. The fit and finish is going to be awesome on this truck!

Re: 1970 Gladiator 1 Ton 6BT 12V Cummins Build

Posted: Mon May 13, 2013 7:10 am

by Resbum

.

Thank you, ross.

Yesterday I made a slight change it layout. I haven't downloaded the pics, but will post one today.

I turned the coolant/windshield fluid unit 90* and raised it up. I didn't like how far the box it sits in intruded into the wheelwell. I like the new arrangement a lot better.

Resbum

Re: 1970 Gladiator 1 Ton 6BT 12V Cummins Build

Posted: Mon May 13, 2013 1:10 pm

by Resbum

.

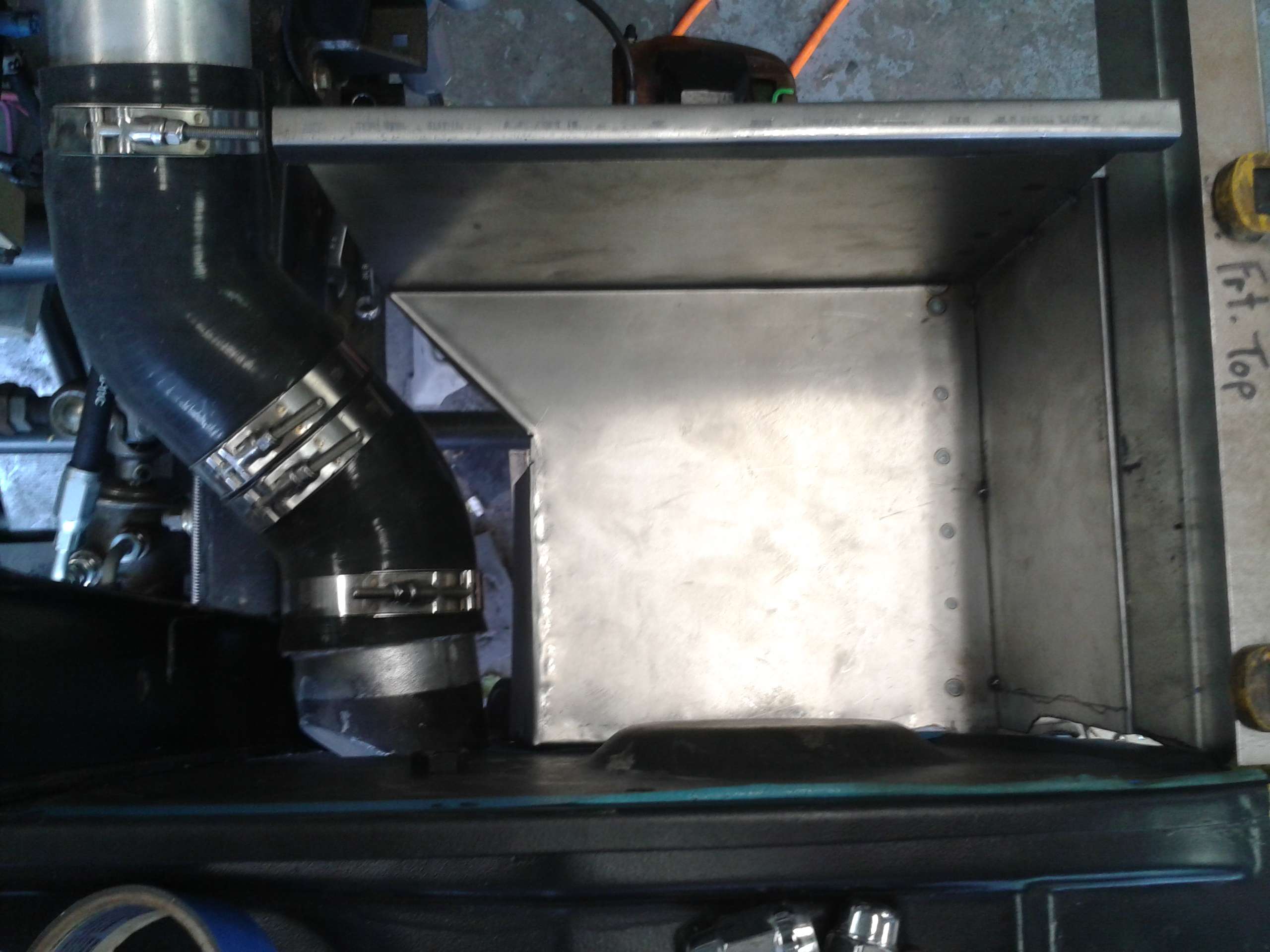

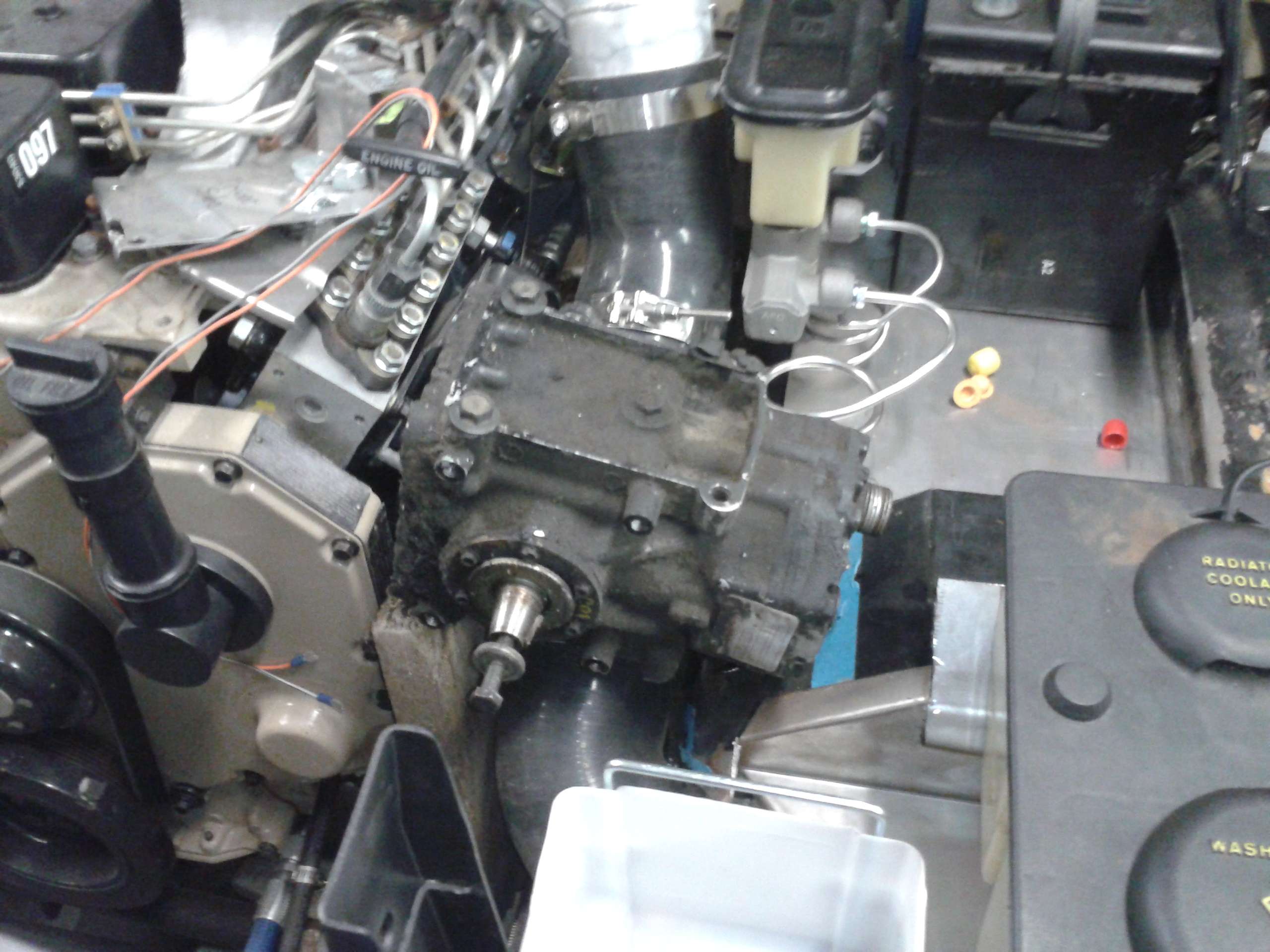

I didn't like how far down the fluid tank box sat, so I rotated the tank 90* and raised it, then re-cut and raised the box almost 3". It left enough room next to the radiator that I cut the top off the overflow tank I was going to use and mounted it as a storage box for rags and other odds and ends.

This is roughly where I'm thinking of mounting the York 210 to be my on-board air compressor. Of course, it will be sitting higher. There are some convenient bolts on the head and timing cover that can be used to attach the compressor bracket assembly, then run a V-belt down to the water pump pulley.

Re: 1970 Gladiator 1 Ton 6BT 12V Cummins Build

Posted: Tue May 21, 2013 8:03 pm

by twisted frame

It's been about a week without an update

Is everything ok?

Re: 1970 Gladiator 1 Ton 6BT 12V Cummins Build

Posted: Tue May 21, 2013 8:37 pm

by Resbum

Yep, thanks for checking. Haha

I've just been doing more of the same to the passenger side inner fender area.

Today I got the battery tray finished and besides minor finishing metal work the engine compartment is for the most part done.

I'll post some pics when everything is together for a final test fit.

Re: 1970 Gladiator 1 Ton 6BT 12V Cummins Build

Posted: Wed May 22, 2013 7:30 am

by ross80truck

Somehow I missed your last post showing the York compressor. Looks good, I am eager to see how you mount it. Have you looked into the Kilby Enterprise kits? They do not make a kit for the 12 Valve 6BT, but I am sure that you could fab a bracket similar to there's to mount the York compressor. I am not to that point on my build yet, but I was planning on building my own kit similar to there's.

Re: 1970 Gladiator 1 Ton 6BT 12V Cummins Build

Posted: Sat May 25, 2013 6:39 pm

by Resbum

.

Made one of the best craigslist scores I've ever had today.

Mile Marker HI9000 hydraulic winch. $125

This deal had been in the works for over a week. During that time I've talked with Mile Marker tech support and White Drive Products, the manufacturer of the hydraulic motor. I'll be able to swap in a different motor that works more efficiently at 2000psi & 10 gallons per minute and step up the pull rating to 10,500lbs. Cost- $204.

For $330 I'll have a winch that can pull an honest 10,500lbs at 21 feet a minute all day long. Since I'm not going to have AC I'm going to mount a hydraulic pump in the AC location and run it off the OEM serpentine belt.

Re: 1970 Gladiator 1 Ton 6BT 12V Cummins Build

Posted: Sun May 26, 2013 10:51 am

by Mudbull

Very cool find! I was hoping to do this one day, but with my limited space I think I'll just be going electric. Can I ask why are you putting in an aux pump? Does the stock not produce enough pressure or volume? Or did you not want to strain it with your steering and brakes already claiming it?

Keep up the good work!