1970 Gladiator 1 Ton 6BT 12V Cummins Build

-

Resbum

Topic author - Posts: 466

- Joined: Fri Jun 08, 2012 9:45 am

- Location: North East Oregon

Re: 1970 Gladiator 1 Ton 6BT 12V Cummins Build

The bars are shackled at the front.

budojeepr kind of hit on it, though. I think the problem has to do with where the front of the track bars/shackles are mounted. When the spring flexes this changes the length between the axle and front spring mount, the radius getting longer and shorter as it travels up and down. This in turn changes the location where the front of the track bars actually wants to pivot around.

This has to do with my earlier post about math I'd struggle with. There is a way to calculate the most desireable location for mounting the track bar to frame shackle pivot point. i.e. track bar length. This would put the the pivot point of the track bar at the "imaginary" pivot point somewhere out in front of the spring mounts.

Based on what I saw when I assembled everything I would have been very close to that "imaginary" pivot point if I'd mounted the track bar shackles to the front of the crossmember, instead of the rear. With the track bars hooked up to the axle, between full droop and the springs compressed to mid point of travel the front pivot point of the track bar changes location by about 1/2". If we take that one step further we could think that between full extension and full compression my track bar pivot point wants to change by about an inch.

I can see where that could hinder my articulation some.

budojeepr kind of hit on it, though. I think the problem has to do with where the front of the track bars/shackles are mounted. When the spring flexes this changes the length between the axle and front spring mount, the radius getting longer and shorter as it travels up and down. This in turn changes the location where the front of the track bars actually wants to pivot around.

This has to do with my earlier post about math I'd struggle with. There is a way to calculate the most desireable location for mounting the track bar to frame shackle pivot point. i.e. track bar length. This would put the the pivot point of the track bar at the "imaginary" pivot point somewhere out in front of the spring mounts.

Based on what I saw when I assembled everything I would have been very close to that "imaginary" pivot point if I'd mounted the track bar shackles to the front of the crossmember, instead of the rear. With the track bars hooked up to the axle, between full droop and the springs compressed to mid point of travel the front pivot point of the track bar changes location by about 1/2". If we take that one step further we could think that between full extension and full compression my track bar pivot point wants to change by about an inch.

I can see where that could hinder my articulation some.

Originally Posted by Resbum

"What year is my truck?... Which part?" Build thread- http://www.fsjnetwork.com/forum/viewtop ... 290#p18290

"What year is my truck?... Which part?" Build thread- http://www.fsjnetwork.com/forum/viewtop ... 290#p18290

-

Resbum

Topic author - Posts: 466

- Joined: Fri Jun 08, 2012 9:45 am

- Location: North East Oregon

Re: 1970 Gladiator 1 Ton 6BT 12V Cummins Build

.

.

Originally posted by Hook574 02-18-2012 03:41 PM

________________________________________

I am not very knowlegable about suspension and I did poorly in geometry class, but it seems to me that if you cycle the suspension and the tracbar shackle doesn't point straight at the axle or collapse against the frame toward the front then you should be good right?

.

Originally posted by Hook574 02-18-2012 03:41 PM

________________________________________

I am not very knowlegable about suspension and I did poorly in geometry class, but it seems to me that if you cycle the suspension and the tracbar shackle doesn't point straight at the axle or collapse against the frame toward the front then you should be good right?

Last edited by Resbum on Sat Apr 06, 2013 6:54 am, edited 1 time in total.

Originally Posted by Resbum

"What year is my truck?... Which part?" Build thread- http://www.fsjnetwork.com/forum/viewtop ... 290#p18290

"What year is my truck?... Which part?" Build thread- http://www.fsjnetwork.com/forum/viewtop ... 290#p18290

-

Resbum

Topic author - Posts: 466

- Joined: Fri Jun 08, 2012 9:45 am

- Location: North East Oregon

Re: 1970 Gladiator 1 Ton 6BT 12V Cummins Build

.

.

Originally posted by tgreening 02-18-2012 11:58 PM

________________________________________

Quote:

________________________________________

Originally Posted by Resbum

The bars are shackled at the front.

budojeepr kind of hit on it, though. I think the problem has to do with where the front of the track bars/shackles are mounted. When the spring flexes this changes the length between the axle and front spring mount, the radius getting longer and shorter as it travels up and down. This in turn changes the location where the front of the track bars actually wants to pivot around.

This has to do with my earlier post about math I'd struggle with. There is a way to calculate the most desireable location for mounting the track bar to frame shackle pivot point. i.e. track bar length. This would put the the pivot point of the track bar at the "imaginary" pivot point somewhere out in front of the spring mounts.

Based on what I saw when I assembled everything I would have been very close to that "imaginary" pivot point if I'd mounted the track bar shackles to the front of the crossmember, instead of the rear. With the track bars hooked up to the axle, between full droop and the springs compressed to mid point of travel the front pivot point of the track bar changes location by about 1/2". If we take that one step further we could think that between full extension and full compression my track bar pivot point wants to change by about an inch.

I can see where that could hinder my articulation some. Resbum________________________________

tgreening says

I "think" I get what you're saying, but I don't think that's going to be the problem. The travel radius of your trac bar is dynamic because the shackle can move for/aft to eliminate any bind. That takes care of suspension compression. When you're or the gas with good traction is when the trac bar is actually trying to rotate. I have mine set so it is trying to pull the shackle up, yours would be trying to push the shackle up. I'm not sure if that would be an issue or not.

It's been a lot of years since I've worked on this problem, but I think where the issue arrises with the dual bar setup is whenone tire is at full stuff and the other at full droop. In this scenario one side of the axle is moving to the rear and the other side to the front. What this does in effect is make your axle a bit twisted out of alignment under your frame. In extreme articulation cases this is what causes axle steer.

What this does to your trac bars is in essence swing them to one side or the other, depending on which side is drooping and which side is compressing.

Now your forward ends of your trac bar are not just pushing up against the shackle and twisting withIN the shackle, but they are trying to push the shackle sideways, and this is where I believe the bind comes from. A single trac bar would have the same problem, just to a lessor extent.

On my jeep I have a single trac bar mounted right beside the pumpkin, and my shackle not only swings for/aft like yours will, but it will also rotate side to side. I have no binding issues and the suspension will actually flex beyond good sense. I'll see if I've got a pic somewhere.

In your case all of this is probably a moot point since your intended wheeling is fairly light. You will on the other hand have excellent wrap control on the road when moving around any heavy loads, or just testing the oomphfability of that big oil burner in there.

tgreening

.

Originally posted by tgreening 02-18-2012 11:58 PM

________________________________________

Quote:

________________________________________

Originally Posted by Resbum

The bars are shackled at the front.

budojeepr kind of hit on it, though. I think the problem has to do with where the front of the track bars/shackles are mounted. When the spring flexes this changes the length between the axle and front spring mount, the radius getting longer and shorter as it travels up and down. This in turn changes the location where the front of the track bars actually wants to pivot around.

This has to do with my earlier post about math I'd struggle with. There is a way to calculate the most desireable location for mounting the track bar to frame shackle pivot point. i.e. track bar length. This would put the the pivot point of the track bar at the "imaginary" pivot point somewhere out in front of the spring mounts.

Based on what I saw when I assembled everything I would have been very close to that "imaginary" pivot point if I'd mounted the track bar shackles to the front of the crossmember, instead of the rear. With the track bars hooked up to the axle, between full droop and the springs compressed to mid point of travel the front pivot point of the track bar changes location by about 1/2". If we take that one step further we could think that between full extension and full compression my track bar pivot point wants to change by about an inch.

I can see where that could hinder my articulation some. Resbum________________________________

tgreening says

I "think" I get what you're saying, but I don't think that's going to be the problem. The travel radius of your trac bar is dynamic because the shackle can move for/aft to eliminate any bind. That takes care of suspension compression. When you're or the gas with good traction is when the trac bar is actually trying to rotate. I have mine set so it is trying to pull the shackle up, yours would be trying to push the shackle up. I'm not sure if that would be an issue or not.

It's been a lot of years since I've worked on this problem, but I think where the issue arrises with the dual bar setup is whenone tire is at full stuff and the other at full droop. In this scenario one side of the axle is moving to the rear and the other side to the front. What this does in effect is make your axle a bit twisted out of alignment under your frame. In extreme articulation cases this is what causes axle steer.

What this does to your trac bars is in essence swing them to one side or the other, depending on which side is drooping and which side is compressing.

Now your forward ends of your trac bar are not just pushing up against the shackle and twisting withIN the shackle, but they are trying to push the shackle sideways, and this is where I believe the bind comes from. A single trac bar would have the same problem, just to a lessor extent.

On my jeep I have a single trac bar mounted right beside the pumpkin, and my shackle not only swings for/aft like yours will, but it will also rotate side to side. I have no binding issues and the suspension will actually flex beyond good sense. I'll see if I've got a pic somewhere.

In your case all of this is probably a moot point since your intended wheeling is fairly light. You will on the other hand have excellent wrap control on the road when moving around any heavy loads, or just testing the oomphfability of that big oil burner in there.

tgreening

Last edited by Resbum on Sat Apr 06, 2013 6:56 am, edited 2 times in total.

Originally Posted by Resbum

"What year is my truck?... Which part?" Build thread- http://www.fsjnetwork.com/forum/viewtop ... 290#p18290

"What year is my truck?... Which part?" Build thread- http://www.fsjnetwork.com/forum/viewtop ... 290#p18290

-

Resbum

Topic author - Posts: 466

- Joined: Fri Jun 08, 2012 9:45 am

- Location: North East Oregon

Re: 1970 Gladiator 1 Ton 6BT 12V Cummins Build

Wow. What a great discussion about track bars/torque bars/anti-wrap bars.

Thanks Hook574, budojeepr, and tgreening for contributing. Regardless of why someone wants them, and if they want one or two, there is some excellent food for thought here.

This tech page is by BillaVista over at Pirate4X4 and has excellent info.

http://www.pirate4x4.com/tech/

Here's his tech article on what he calls anti-wrap bars, and is what I used to think my way through the set I built. It sounds like tgreening's is very similiar to his design.

http://www.pirate4x4.com/tech/billav...ntiwrapbar.htm

This is an excellent article BillaVista makes reference to in his anti-wrap bar article, and it does a good job of discussing why bars help a suspension and some of their pitfalls.

http://www.4x4wire.com/jeep/tech/susp/axlewrap/

Resbum

Thanks Hook574, budojeepr, and tgreening for contributing. Regardless of why someone wants them, and if they want one or two, there is some excellent food for thought here.

This tech page is by BillaVista over at Pirate4X4 and has excellent info.

http://www.pirate4x4.com/tech/

Here's his tech article on what he calls anti-wrap bars, and is what I used to think my way through the set I built. It sounds like tgreening's is very similiar to his design.

http://www.pirate4x4.com/tech/billav...ntiwrapbar.htm

This is an excellent article BillaVista makes reference to in his anti-wrap bar article, and it does a good job of discussing why bars help a suspension and some of their pitfalls.

http://www.4x4wire.com/jeep/tech/susp/axlewrap/

Resbum

Originally Posted by Resbum

"What year is my truck?... Which part?" Build thread- http://www.fsjnetwork.com/forum/viewtop ... 290#p18290

"What year is my truck?... Which part?" Build thread- http://www.fsjnetwork.com/forum/viewtop ... 290#p18290

-

Resbum

Topic author - Posts: 466

- Joined: Fri Jun 08, 2012 9:45 am

- Location: North East Oregon

Re: 1970 Gladiator 1 Ton 6BT 12V Cummins Build

Quote:

________________________________________

Originally Posted by Hook574

I am not very knowlegable about suspension and I did poorley in geometry class, but it seems to me that if you cycle the suspension and the tracbar shackle dosen't point straight at the axle or collapse against the frame toward the front then you should be good right?

________________________________________

Hook574, I tried to make mine so that the angle at the front pivot point/shackle was as close to 90 degrees as possible. I used the axle centerline to front pivot point, then up through the shackle to the shackle frame mount for my references. Because the bars primary purpose is to stop rotational forces, having a true 90 angle at the shackle joint translates 100% of those forces to the frame/mounting point.

Resbum

________________________________________

Originally Posted by Hook574

I am not very knowlegable about suspension and I did poorley in geometry class, but it seems to me that if you cycle the suspension and the tracbar shackle dosen't point straight at the axle or collapse against the frame toward the front then you should be good right?

________________________________________

Hook574, I tried to make mine so that the angle at the front pivot point/shackle was as close to 90 degrees as possible. I used the axle centerline to front pivot point, then up through the shackle to the shackle frame mount for my references. Because the bars primary purpose is to stop rotational forces, having a true 90 angle at the shackle joint translates 100% of those forces to the frame/mounting point.

Resbum

Originally Posted by Resbum

"What year is my truck?... Which part?" Build thread- http://www.fsjnetwork.com/forum/viewtop ... 290#p18290

"What year is my truck?... Which part?" Build thread- http://www.fsjnetwork.com/forum/viewtop ... 290#p18290

-

Resbum

Topic author - Posts: 466

- Joined: Fri Jun 08, 2012 9:45 am

- Location: North East Oregon

Re: 1970 Gladiator 1 Ton 6BT 12V Cummins Build

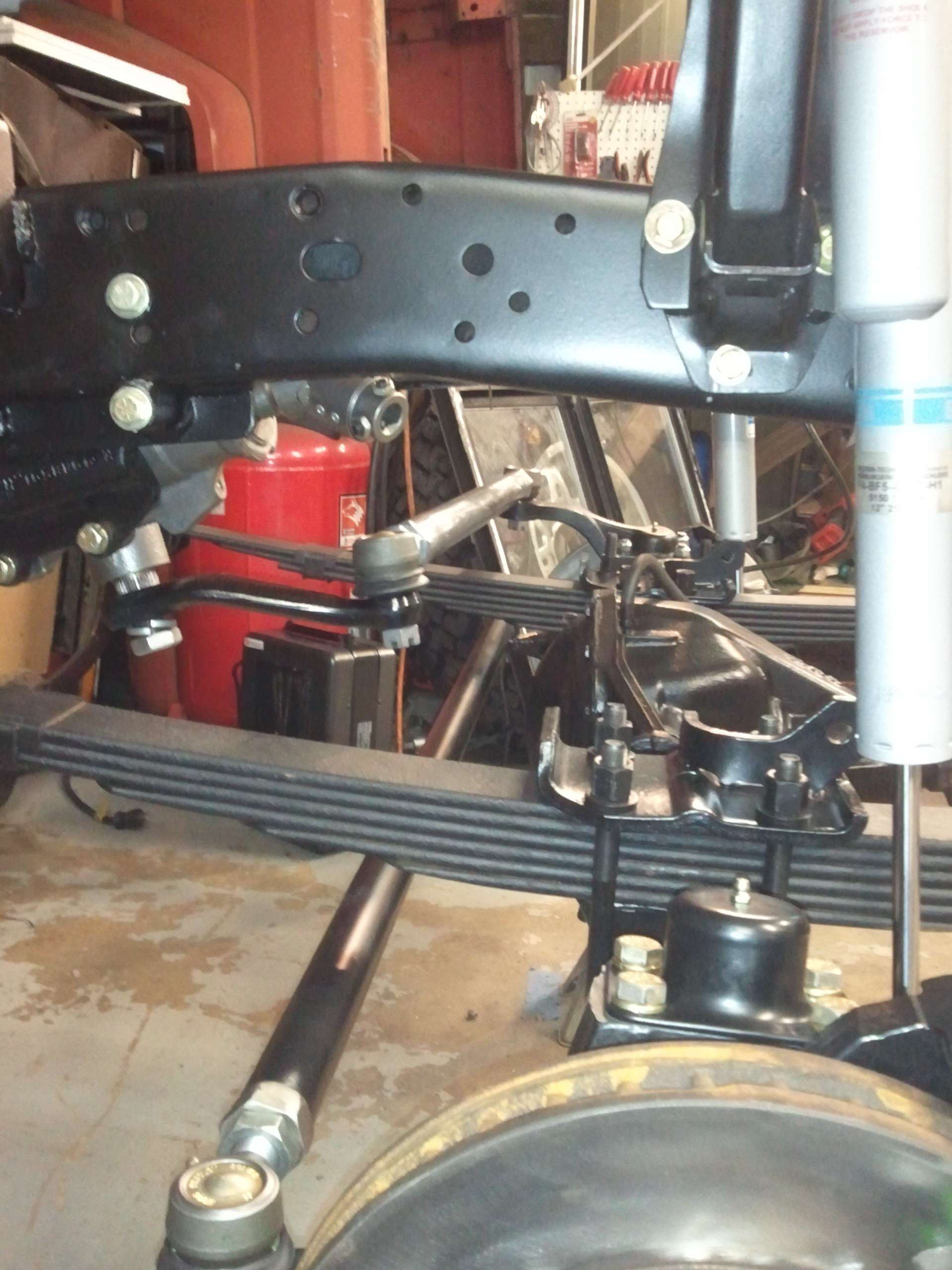

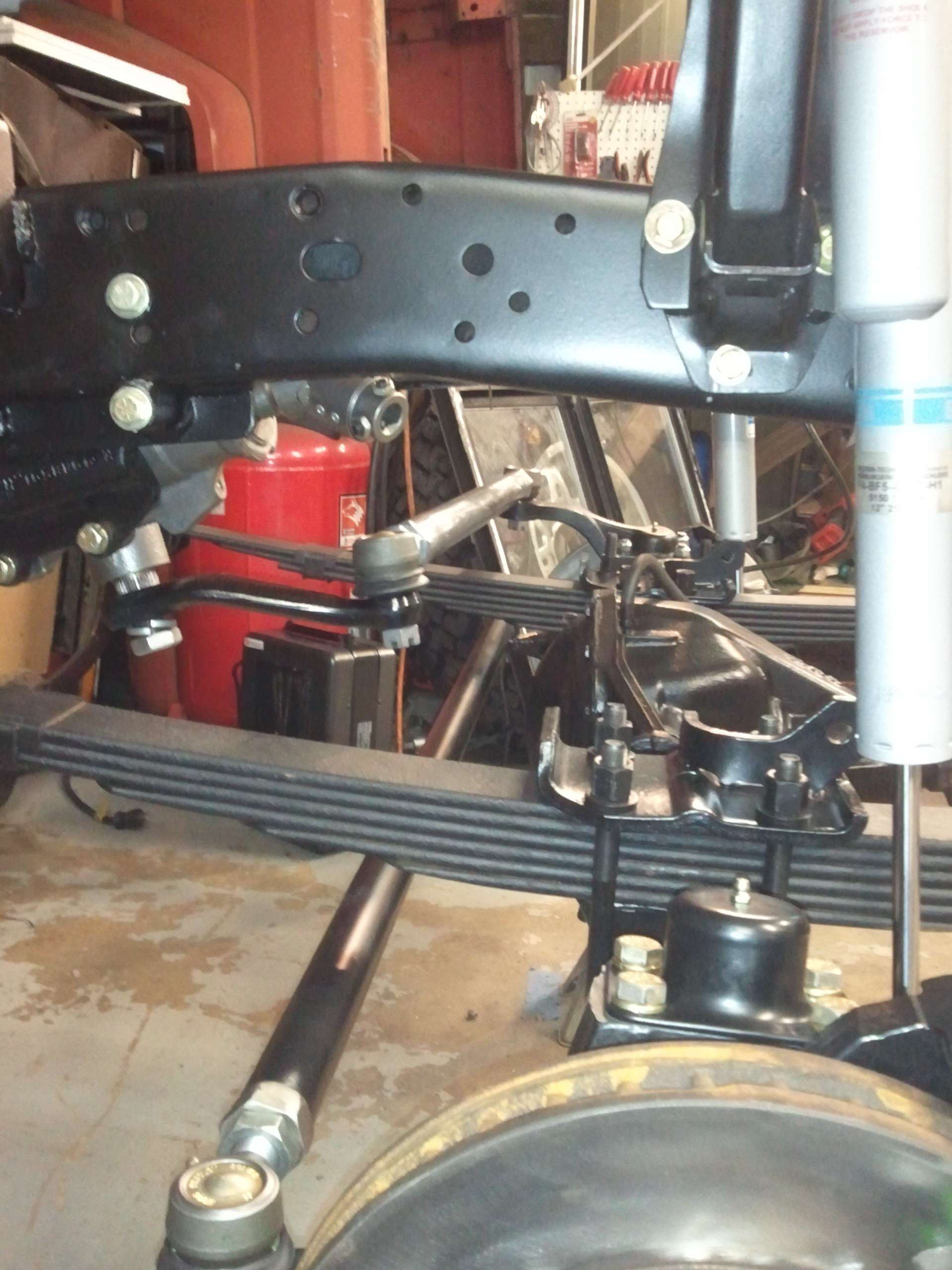

The front brakes, shocks, and steering box are finally on. I did some of it while I was sick and finished the rest yesterday. I still have to orientate the external reservoirs where I want them, but need to wait.

Originally Posted by Resbum

"What year is my truck?... Which part?" Build thread- http://www.fsjnetwork.com/forum/viewtop ... 290#p18290

"What year is my truck?... Which part?" Build thread- http://www.fsjnetwork.com/forum/viewtop ... 290#p18290

-

Resbum

Topic author - Posts: 466

- Joined: Fri Jun 08, 2012 9:45 am

- Location: North East Oregon

Re: 1970 Gladiator 1 Ton 6BT 12V Cummins Build

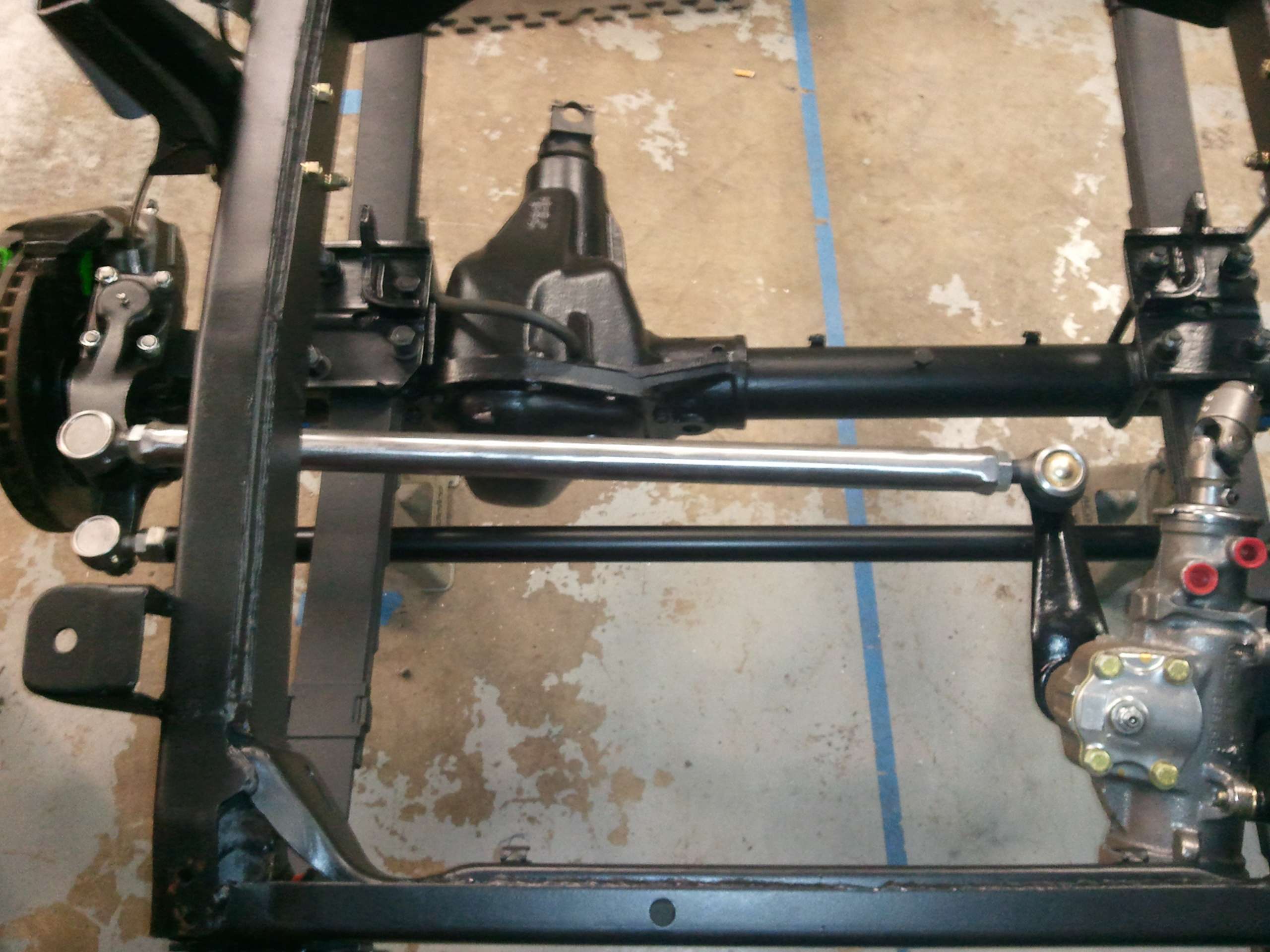

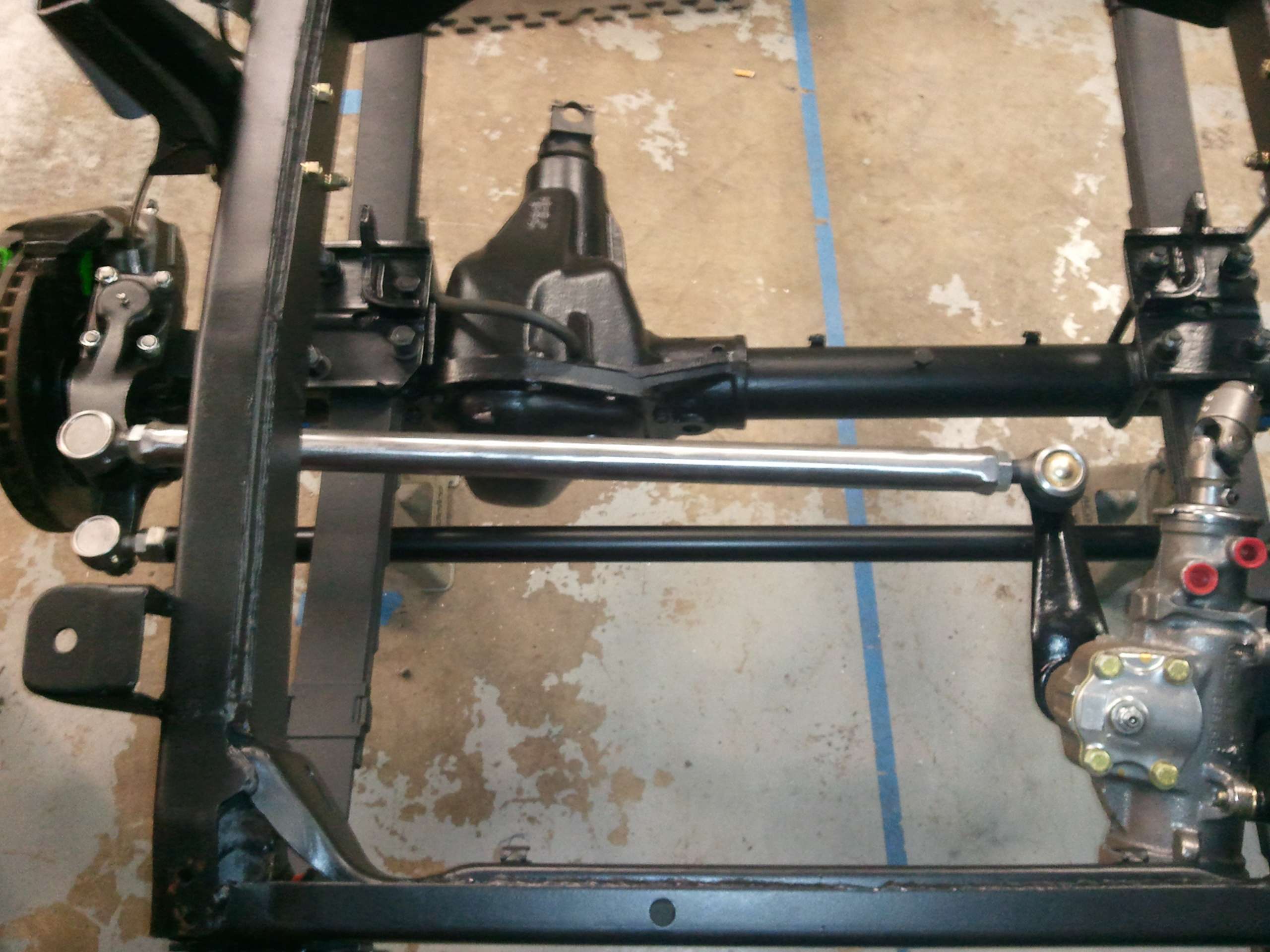

Today I wrapped up the draglink. After the pictures it came back off and got paint. I’m very pleased with how well the geometry of everything came out.

Originally Posted by Resbum

"What year is my truck?... Which part?" Build thread- http://www.fsjnetwork.com/forum/viewtop ... 290#p18290

"What year is my truck?... Which part?" Build thread- http://www.fsjnetwork.com/forum/viewtop ... 290#p18290

-

Resbum

Topic author - Posts: 466

- Joined: Fri Jun 08, 2012 9:45 am

- Location: North East Oregon

Re: 1970 Gladiator 1 Ton 6BT 12V Cummins Build

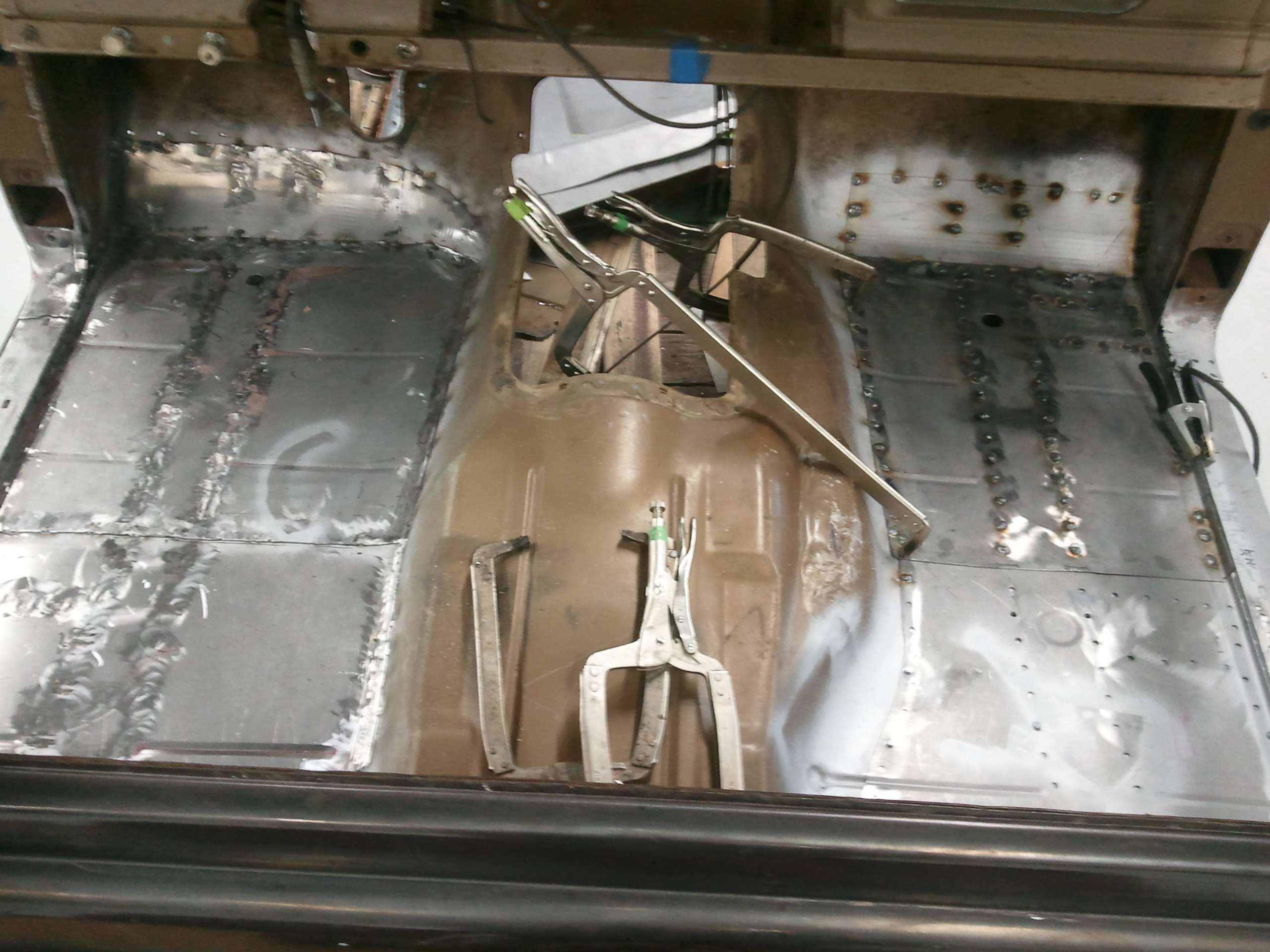

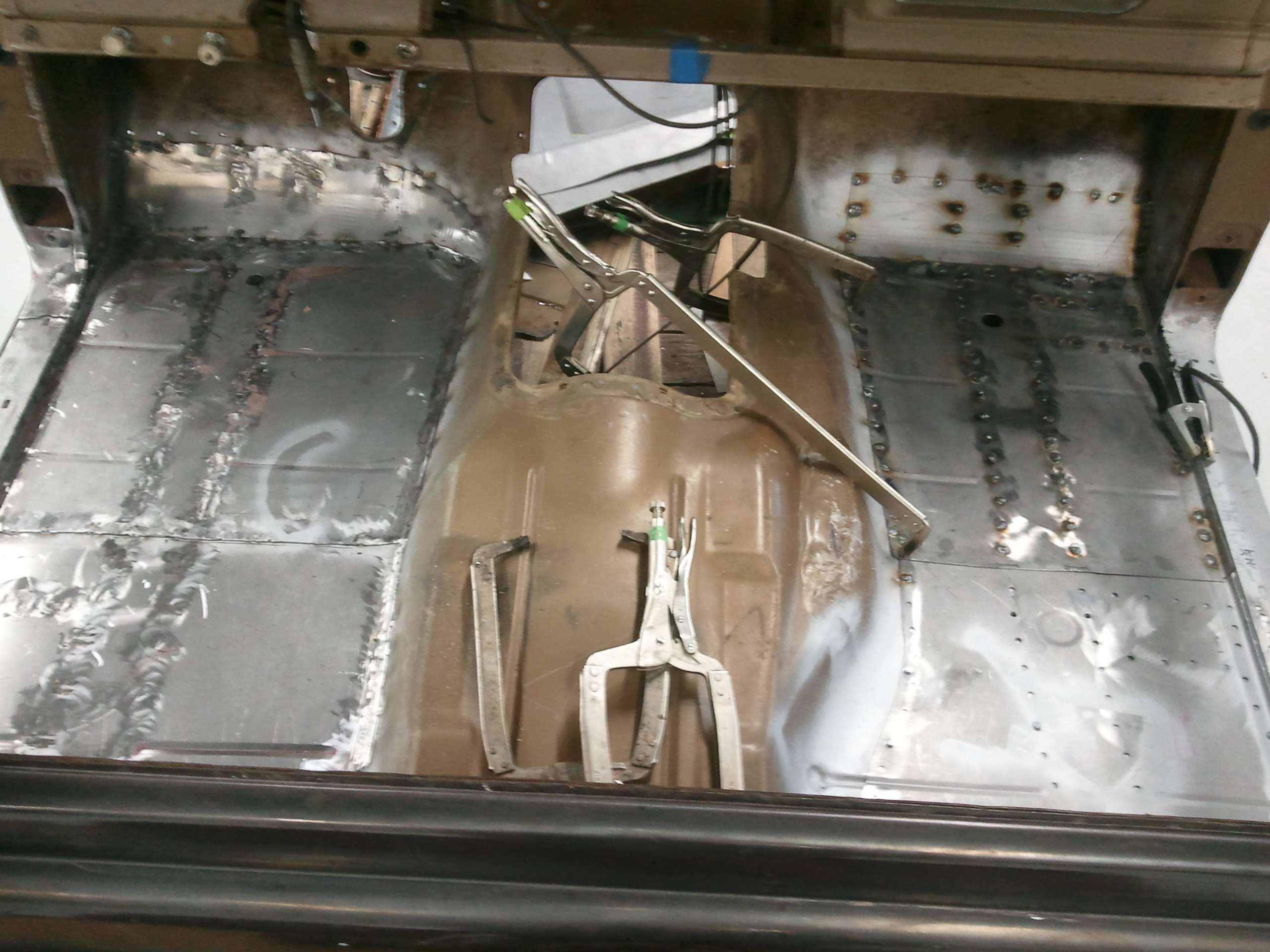

I might as well show some pics of the ongoing cab work. Originally, I thought the truck cab could be saved. I’d even ordered the replacement floor pan’s for it. As I exposed everything I realized how bad the floors truly were. Then, when I removed the windows I saw all the rot under the window rubbers.

So, it was off to craigslist again for a donor. I ended up buying a whole truck. Before I even towed it home I posted the engine, trans, and transfer case on craigslist. The day I picked up the donor truck I towed it straight to a guy’s house who had bought those. He removed everything, gave me $50 more than I’d paid for the truck, and I towed it to the shop. Besides the cab, I kept all the sheetmetal (no bed), and other odds and ends for spares in the future.

Got it all stripped down

Stopped by the pressure washer, then off to the bodyshop.

So, it was off to craigslist again for a donor. I ended up buying a whole truck. Before I even towed it home I posted the engine, trans, and transfer case on craigslist. The day I picked up the donor truck I towed it straight to a guy’s house who had bought those. He removed everything, gave me $50 more than I’d paid for the truck, and I towed it to the shop. Besides the cab, I kept all the sheetmetal (no bed), and other odds and ends for spares in the future.

Got it all stripped down

Stopped by the pressure washer, then off to the bodyshop.

Originally Posted by Resbum

"What year is my truck?... Which part?" Build thread- http://www.fsjnetwork.com/forum/viewtop ... 290#p18290

"What year is my truck?... Which part?" Build thread- http://www.fsjnetwork.com/forum/viewtop ... 290#p18290

-

Resbum

Topic author - Posts: 466

- Joined: Fri Jun 08, 2012 9:45 am

- Location: North East Oregon

Re: 1970 Gladiator 1 Ton 6BT 12V Cummins Build

Arghhh! Been fighting a couple issues plumbing in the brakes hard lines. Since stopping is more important than going I haven't been rushing it.

Resbum

Resbum

Originally Posted by Resbum

"What year is my truck?... Which part?" Build thread- http://www.fsjnetwork.com/forum/viewtop ... 290#p18290

"What year is my truck?... Which part?" Build thread- http://www.fsjnetwork.com/forum/viewtop ... 290#p18290

-

Resbum

Topic author - Posts: 466

- Joined: Fri Jun 08, 2012 9:45 am

- Location: North East Oregon

Re: 1970 Gladiator 1 Ton 6BT 12V Cummins Build

I'm finally wrapping up the brake lines today. Yesterday the school asked if I could bring the truck (rolling chassis) by so they can have it to mock up notching the firewall for engine clearance. I'll temporarily drop the engine and drivetrain in and tow it over.

This is a good time for me to take a break. I've been working on the truck for 8 months non-stop. While the school has the truck for the next week, or so, I'm going to load up a bunch of building materials I've been collecting and run down to my property in Oregon.

Resbum

This is a good time for me to take a break. I've been working on the truck for 8 months non-stop. While the school has the truck for the next week, or so, I'm going to load up a bunch of building materials I've been collecting and run down to my property in Oregon.

Resbum

Originally Posted by Resbum

"What year is my truck?... Which part?" Build thread- http://www.fsjnetwork.com/forum/viewtop ... 290#p18290

"What year is my truck?... Which part?" Build thread- http://www.fsjnetwork.com/forum/viewtop ... 290#p18290

-

Resbum

Topic author - Posts: 466

- Joined: Fri Jun 08, 2012 9:45 am

- Location: North East Oregon

Re: 1970 Gladiator 1 Ton 6BT 12V Cummins Build

I finally got the brake lines plumbed in. The kit I bought was for a newer model. I didn't think it would be that much different. I was wrong. I had to straighten and rebend a lot of the lines. Eventually I got everything to fit, though. I still need to make a couple tabs to secure the line to the rear axle and mount the bracket to the frame for the soft line down to the axle.

Originally Posted by Resbum

"What year is my truck?... Which part?" Build thread- http://www.fsjnetwork.com/forum/viewtop ... 290#p18290

"What year is my truck?... Which part?" Build thread- http://www.fsjnetwork.com/forum/viewtop ... 290#p18290

-

Resbum

Topic author - Posts: 466

- Joined: Fri Jun 08, 2012 9:45 am

- Location: North East Oregon

Re: 1970 Gladiator 1 Ton 6BT 12V Cummins Build

Quote:

________________________________________

Originally Posted by twisted frame

Did you bend your own brake lines? That bend near the crossmember looks sweet. If so, did you lay it out with rod first to get the bends? Did you use one of those cheapy benders or a better kind?

________________________________________

I guess you could say I bent my own brakelines. I bought a kit for a newer model year thinking they would be close and they were totally different. For the most part I ended up having to straighten and rebend all the lines. Because tubing work-hardens I was very careful to only straighten and rebend one time, so I worked slow.

I didn't lay it out with rod first, but I would have had I been starting from scratch.

For most of the straightening and bending I used one of the better benders, but I also used a cheaper one if it fit and I couldn't get the good one to fit.

Warning- Unsolicited advice coming:

I also had to redo a lot of the ends. For that I used a GOOD quality DOUBLE flare tool. I think mine cost $60. This is something that IS NOT optional. All brake and fuel lines should be done with a good quality double flare.

OK, I'll climb back down off the soapbox now.

Resbum

________________________________________

Originally Posted by twisted frame

Did you bend your own brake lines? That bend near the crossmember looks sweet. If so, did you lay it out with rod first to get the bends? Did you use one of those cheapy benders or a better kind?

________________________________________

I guess you could say I bent my own brakelines. I bought a kit for a newer model year thinking they would be close and they were totally different. For the most part I ended up having to straighten and rebend all the lines. Because tubing work-hardens I was very careful to only straighten and rebend one time, so I worked slow.

I didn't lay it out with rod first, but I would have had I been starting from scratch.

For most of the straightening and bending I used one of the better benders, but I also used a cheaper one if it fit and I couldn't get the good one to fit.

Warning- Unsolicited advice coming:

I also had to redo a lot of the ends. For that I used a GOOD quality DOUBLE flare tool. I think mine cost $60. This is something that IS NOT optional. All brake and fuel lines should be done with a good quality double flare.

OK, I'll climb back down off the soapbox now.

Resbum

Originally Posted by Resbum

"What year is my truck?... Which part?" Build thread- http://www.fsjnetwork.com/forum/viewtop ... 290#p18290

"What year is my truck?... Which part?" Build thread- http://www.fsjnetwork.com/forum/viewtop ... 290#p18290

-

Resbum

Topic author - Posts: 466

- Joined: Fri Jun 08, 2012 9:45 am

- Location: North East Oregon

Re: 1970 Gladiator 1 Ton 6BT 12V Cummins Build

It's the disc/disc proportioning value from BJ's Offroad

http://www.bjsoffroad.com/prod-746.htm

Use the "Choose your item" drop down on the right side of the page to select disc/disc

http://www.bjsoffroad.com/prod-746.htm

Use the "Choose your item" drop down on the right side of the page to select disc/disc

Originally Posted by Resbum

"What year is my truck?... Which part?" Build thread- http://www.fsjnetwork.com/forum/viewtop ... 290#p18290

"What year is my truck?... Which part?" Build thread- http://www.fsjnetwork.com/forum/viewtop ... 290#p18290

-

Resbum

Topic author - Posts: 466

- Joined: Fri Jun 08, 2012 9:45 am

- Location: North East Oregon

Re: 1970 Gladiator 1 Ton 6BT 12V Cummins Build

.

Originally posted by lobie

Quote:

________________________________________

Originally Posted by Resbum

It's the disc/disc proportioning value from BJ's Offroad

http://www.bjsoffroad.com/prod-746.htm

Use the "Choose your item" drop down on the right side of the page to select disc/disc

Resbum

________________________________________

Thanks. I've looked at that one. I also have an adjustable one from a previous project. I think I'm gonna try the one I have first.

Originally posted by lobie

Quote:

________________________________________

Originally Posted by Resbum

It's the disc/disc proportioning value from BJ's Offroad

http://www.bjsoffroad.com/prod-746.htm

Use the "Choose your item" drop down on the right side of the page to select disc/disc

Resbum

________________________________________

Thanks. I've looked at that one. I also have an adjustable one from a previous project. I think I'm gonna try the one I have first.

Last edited by Resbum on Sat Apr 06, 2013 7:10 am, edited 1 time in total.

Originally Posted by Resbum

"What year is my truck?... Which part?" Build thread- http://www.fsjnetwork.com/forum/viewtop ... 290#p18290

"What year is my truck?... Which part?" Build thread- http://www.fsjnetwork.com/forum/viewtop ... 290#p18290

-

Resbum

Topic author - Posts: 466

- Joined: Fri Jun 08, 2012 9:45 am

- Location: North East Oregon

Re: 1970 Gladiator 1 Ton 6BT 12V Cummins Build

I have an adjustable one, too. I was thinking of running them in parallel with each other.

When the manual one is set to a higher restriction than the automatic one the automatic one will do its job. That would be most of the time. When I have to haul an extremely heavy load I could crank up more pressure (less restriction) to the rear brakes with the manual valve and the rear brake pressure would divert through it.

Right now that's just a thought.

Resbum

When the manual one is set to a higher restriction than the automatic one the automatic one will do its job. That would be most of the time. When I have to haul an extremely heavy load I could crank up more pressure (less restriction) to the rear brakes with the manual valve and the rear brake pressure would divert through it.

Right now that's just a thought.

Resbum

Originally Posted by Resbum

"What year is my truck?... Which part?" Build thread- http://www.fsjnetwork.com/forum/viewtop ... 290#p18290

"What year is my truck?... Which part?" Build thread- http://www.fsjnetwork.com/forum/viewtop ... 290#p18290

-

Resbum

Topic author - Posts: 466

- Joined: Fri Jun 08, 2012 9:45 am

- Location: North East Oregon

Re: 1970 Gladiator 1 Ton 6BT 12V Cummins Build

Today was a good boost to the morale. I wasn't expecting to feel good just seeing the engine and drivetrain temporarily installed. Once I got it out of the shop and saw it in daylight I felt good.

The truck will spent the next week or so at the school getting the cab fitted.

The truck will spent the next week or so at the school getting the cab fitted.

Last edited by Resbum on Sat Apr 06, 2013 7:15 am, edited 1 time in total.

Originally Posted by Resbum

"What year is my truck?... Which part?" Build thread- http://www.fsjnetwork.com/forum/viewtop ... 290#p18290

"What year is my truck?... Which part?" Build thread- http://www.fsjnetwork.com/forum/viewtop ... 290#p18290

-

Resbum

Topic author - Posts: 466

- Joined: Fri Jun 08, 2012 9:45 am

- Location: North East Oregon

Re: 1970 Gladiator 1 Ton 6BT 12V Cummins Build

When I got to the school they had already got a headstart on notching the firewall. Tomorrow they'll put the cab on the frame and I'll swing by a get a few pictures.

Last edited by Resbum on Sat Apr 06, 2013 7:16 am, edited 1 time in total.

Originally Posted by Resbum

"What year is my truck?... Which part?" Build thread- http://www.fsjnetwork.com/forum/viewtop ... 290#p18290

"What year is my truck?... Which part?" Build thread- http://www.fsjnetwork.com/forum/viewtop ... 290#p18290

-

Resbum

Topic author - Posts: 466

- Joined: Fri Jun 08, 2012 9:45 am

- Location: North East Oregon

Re: 1970 Gladiator 1 Ton 6BT 12V Cummins Build

Today, when I stopped by the school, I was informed of a SNAFU that needs to be overcome. It's going to be tighter on the driver’s side of the notch than we expected. We talked about options and the school will take it from here. It should turn out fine, just a little more work than we expected.

Last edited by Resbum on Sat Apr 06, 2013 7:19 am, edited 1 time in total.

Originally Posted by Resbum

"What year is my truck?... Which part?" Build thread- http://www.fsjnetwork.com/forum/viewtop ... 290#p18290

"What year is my truck?... Which part?" Build thread- http://www.fsjnetwork.com/forum/viewtop ... 290#p18290

-

Resbum

Topic author - Posts: 466

- Joined: Fri Jun 08, 2012 9:45 am

- Location: North East Oregon

Re: 1970 Gladiator 1 Ton 6BT 12V Cummins Build

I know that it’s going to be very close from when I was mocking it all up. If nothing else, it almost certainly is going to take either mod'ing the down pipe or looking for a different manifold.

After I took these pictures I ran to the shop and grabbed the turbo, down pipe, steering column, wiper motor, and a few other parts. By the time I got back to the school they were stopping for the day.

We'll have a better idea by Monday afternoon.

Resbum

P.S. Have I metioned how VERY GRATEFUL I am to the school for taking this part of the build on for me? If I haven't, I am VERY GRATEFUL that they're doing this for me!!!

After I took these pictures I ran to the shop and grabbed the turbo, down pipe, steering column, wiper motor, and a few other parts. By the time I got back to the school they were stopping for the day.

We'll have a better idea by Monday afternoon.

Resbum

P.S. Have I metioned how VERY GRATEFUL I am to the school for taking this part of the build on for me? If I haven't, I am VERY GRATEFUL that they're doing this for me!!!

Originally Posted by Resbum

"What year is my truck?... Which part?" Build thread- http://www.fsjnetwork.com/forum/viewtop ... 290#p18290

"What year is my truck?... Which part?" Build thread- http://www.fsjnetwork.com/forum/viewtop ... 290#p18290

-

Resbum

Topic author - Posts: 466

- Joined: Fri Jun 08, 2012 9:45 am

- Location: North East Oregon

Re: 1970 Gladiator 1 Ton 6BT 12V Cummins Build

Quote:

________________________________________

Originally Posted by lobie

Have u fit the down pipe off the turbo yet. Looks like u may have to notch the firewall or use a different exhaust manifold.

________________________________________

Just an update before I bug-out for Oregon for the next 4 days. When I get home at the beginning of next week the school should be done with the passenger cab work.

I've come up against the first major self-induced SNAFU of my build. On one hand, I can't complain because I've made it this far into the build with no major surprises. On the other hand, I now need to tackle something else that I wasn't expecting to.

I don't know how I did it, but I was off by 4 inches on the clearances I thought I had around the back of the engine/turbo and firewall. There was really no other way to get everything from the intercooler, larger radiator, and engine to fit properly. I just screwed up on how far it was going to encroach into the firewall area. Right now, as it stands, in the above quote lobie was on to this problem before I was. Good eye. I owe you a Fresca or beverage of your choice if we ever hook up.

I owe you a Fresca or beverage of your choice if we ever hook up.

My turbo exhaust outlet is literally at the firewall. Not one bit of room for the downpipe.

While I've been getting ready to go to Oregon this week I've also been running around talking to people I know about possible fixes. From previous projects I know of George, at Turbo Technologies. He has 30+ years of experience as an artist with turbo’s. He was one of my stops and came up with probably the simplest and most elegant fix.

Edit- This issue gets addressed in-depth during the engine build part later in the thread

Resbum

________________________________________

Originally Posted by lobie

Have u fit the down pipe off the turbo yet. Looks like u may have to notch the firewall or use a different exhaust manifold.

________________________________________

Just an update before I bug-out for Oregon for the next 4 days. When I get home at the beginning of next week the school should be done with the passenger cab work.

I've come up against the first major self-induced SNAFU of my build. On one hand, I can't complain because I've made it this far into the build with no major surprises. On the other hand, I now need to tackle something else that I wasn't expecting to.

I don't know how I did it, but I was off by 4 inches on the clearances I thought I had around the back of the engine/turbo and firewall. There was really no other way to get everything from the intercooler, larger radiator, and engine to fit properly. I just screwed up on how far it was going to encroach into the firewall area. Right now, as it stands, in the above quote lobie was on to this problem before I was. Good eye.

My turbo exhaust outlet is literally at the firewall. Not one bit of room for the downpipe.

While I've been getting ready to go to Oregon this week I've also been running around talking to people I know about possible fixes. From previous projects I know of George, at Turbo Technologies. He has 30+ years of experience as an artist with turbo’s. He was one of my stops and came up with probably the simplest and most elegant fix.

Edit- This issue gets addressed in-depth during the engine build part later in the thread

Resbum

Originally Posted by Resbum

"What year is my truck?... Which part?" Build thread- http://www.fsjnetwork.com/forum/viewtop ... 290#p18290

"What year is my truck?... Which part?" Build thread- http://www.fsjnetwork.com/forum/viewtop ... 290#p18290