Here you go?

My disclaimer...any of the more experienced builders have any inputs, please let me know...I am no way, shape or form an expert...

X10...especially if you don't remove the exhaust manifolds.jaber wrote:Be gentle around the heater box, it will break easy. 4 nuts and it will come off the firewall.

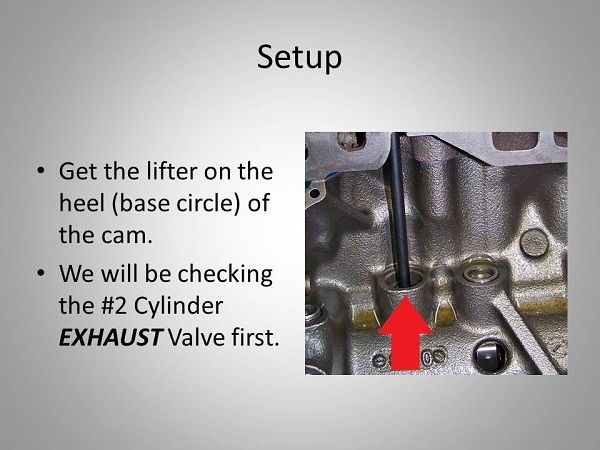

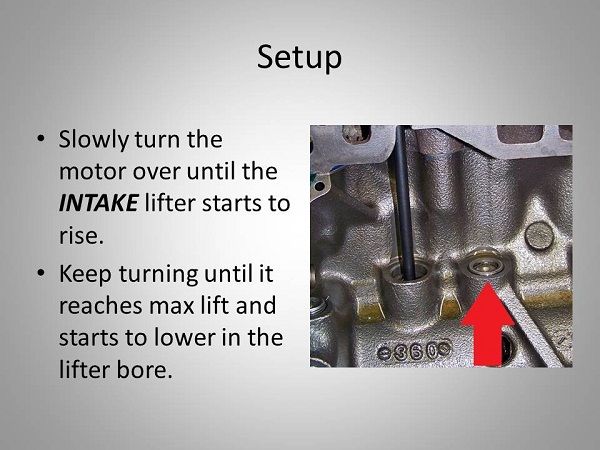

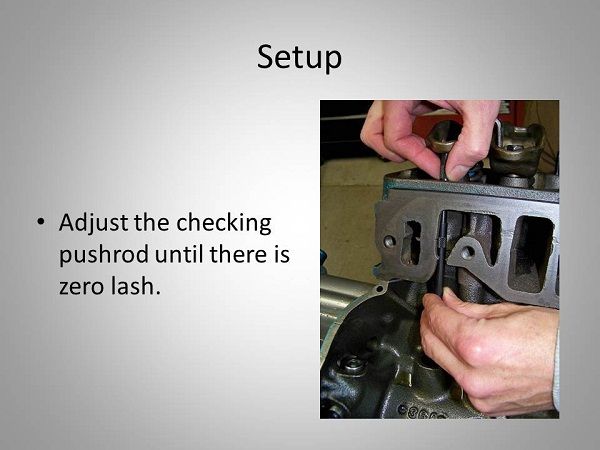

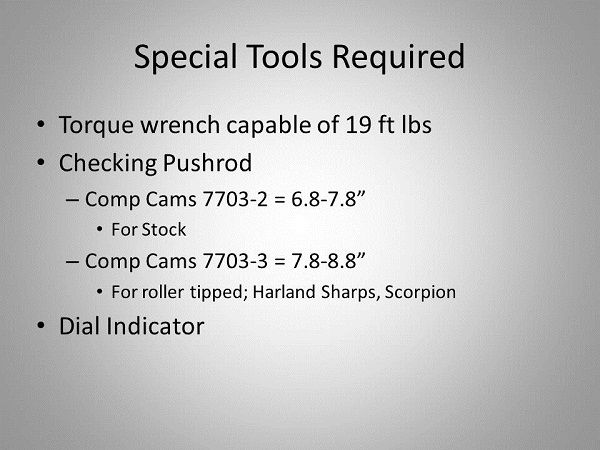

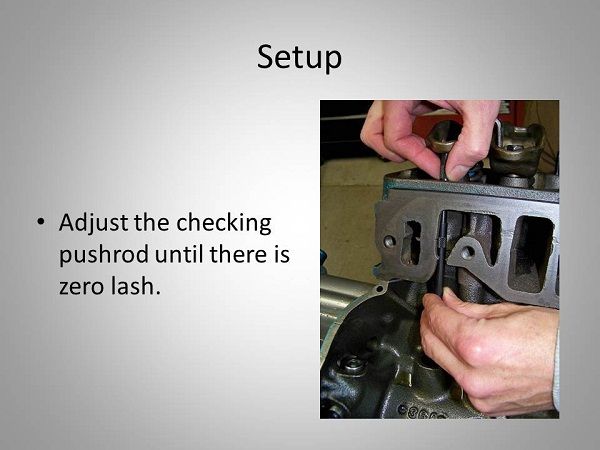

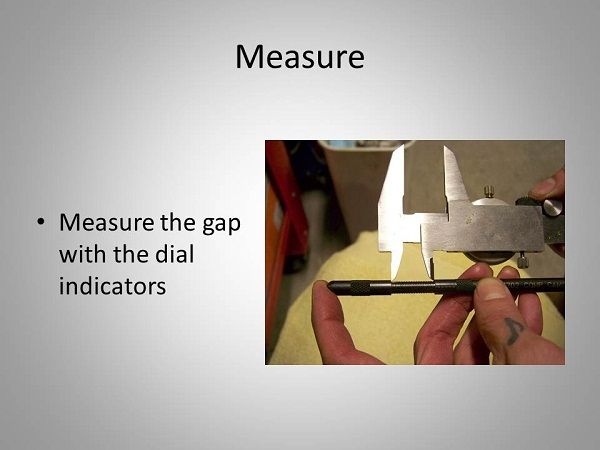

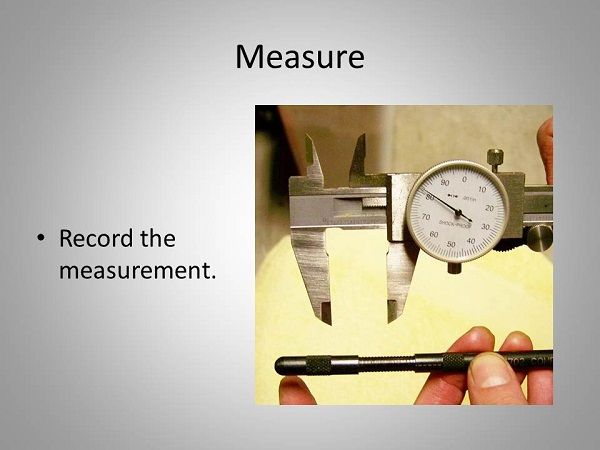

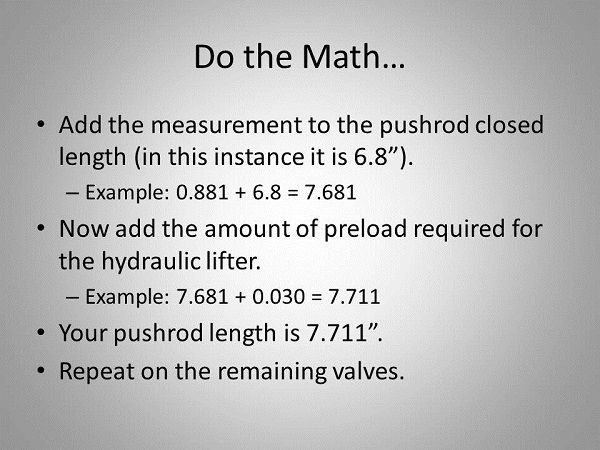

1) Should be done with hydraulic lifters.pharmdut wrote:Hey billyj7175......should I perform this test on hydraulic lifters or solid lifters? What exactly is zero lash? I did this today on hydraulic lifters on the number one cylinder at TDC. The testing rod seems to just be pushing the heel of the lifter down as I lengthen it. I am still able to turn the pushrod between my fingers. Given, it is tight to turn though. I apologize if this is such an amateur question.

Thanks in advance for the help!!

theQman wrote:http://www.carcraft.com/techarticles/11 ... ewall.html

Check this out. I saw your video and I think something is off too but I'm not sure what to do.