I had an email recently from a Cherokee owner that wanted some drip rails fabricated to take care of some rust issues around his windshield. I had done on-off reproductions for other vehicles and he contacted me as he had little luck in sourcing used parts. I asked him to send me a small sample of the cross section and I would try it. Here's a thread to show the fabrication, may help others to form their own repairs..

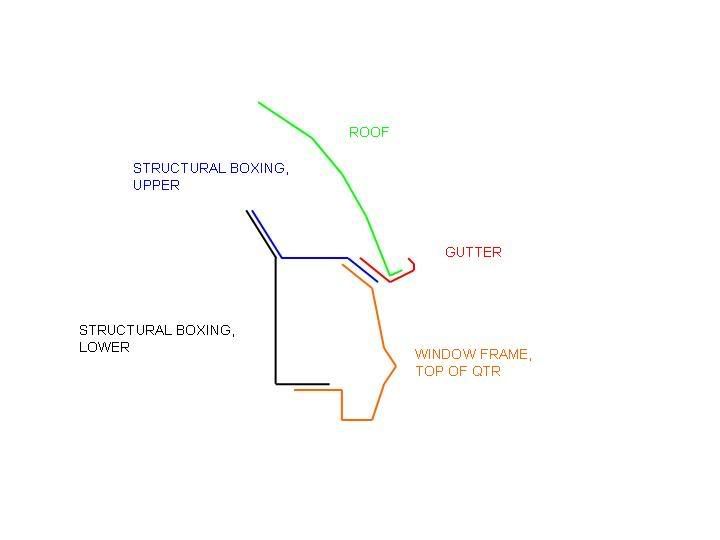

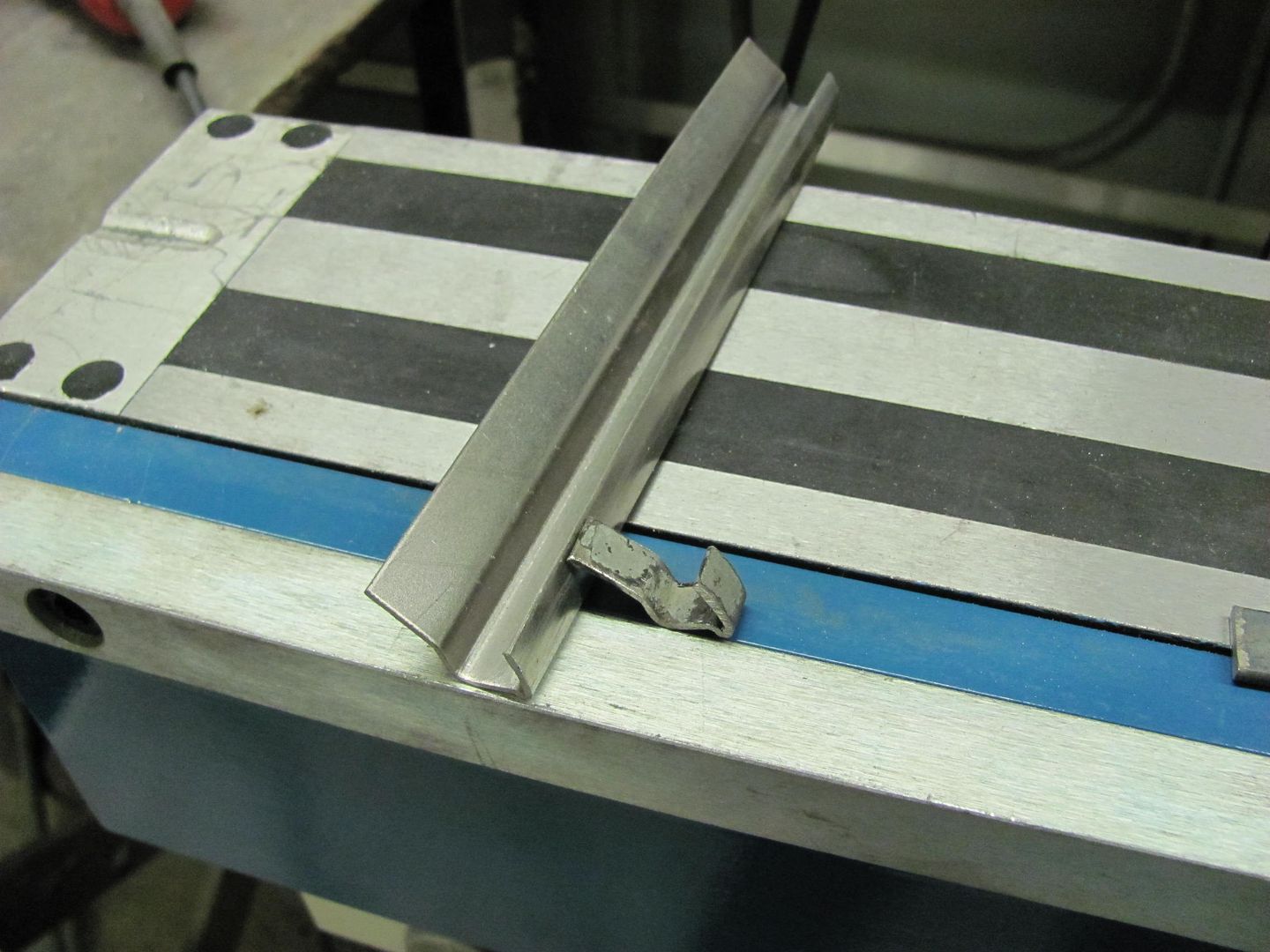

Sample I received:

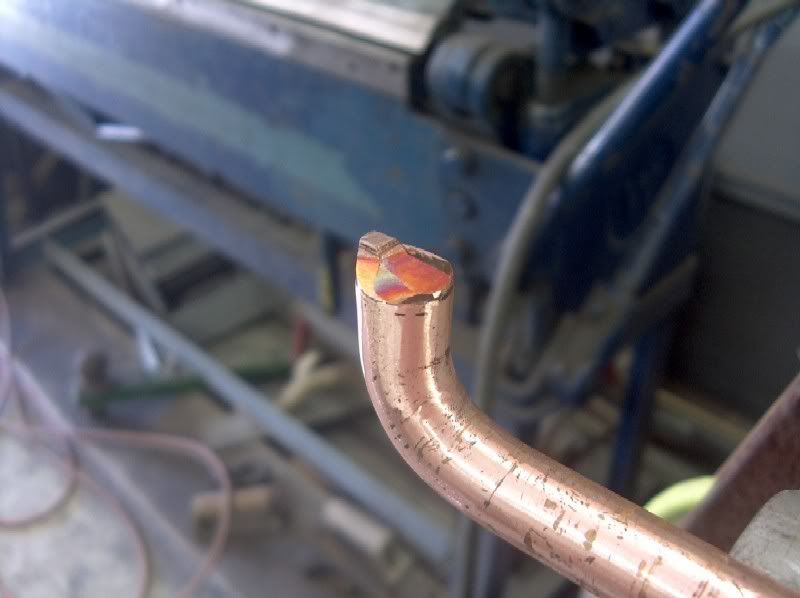

The fabrication sample was done with 18ga crs using the bead roller, mag brake, and press brake.

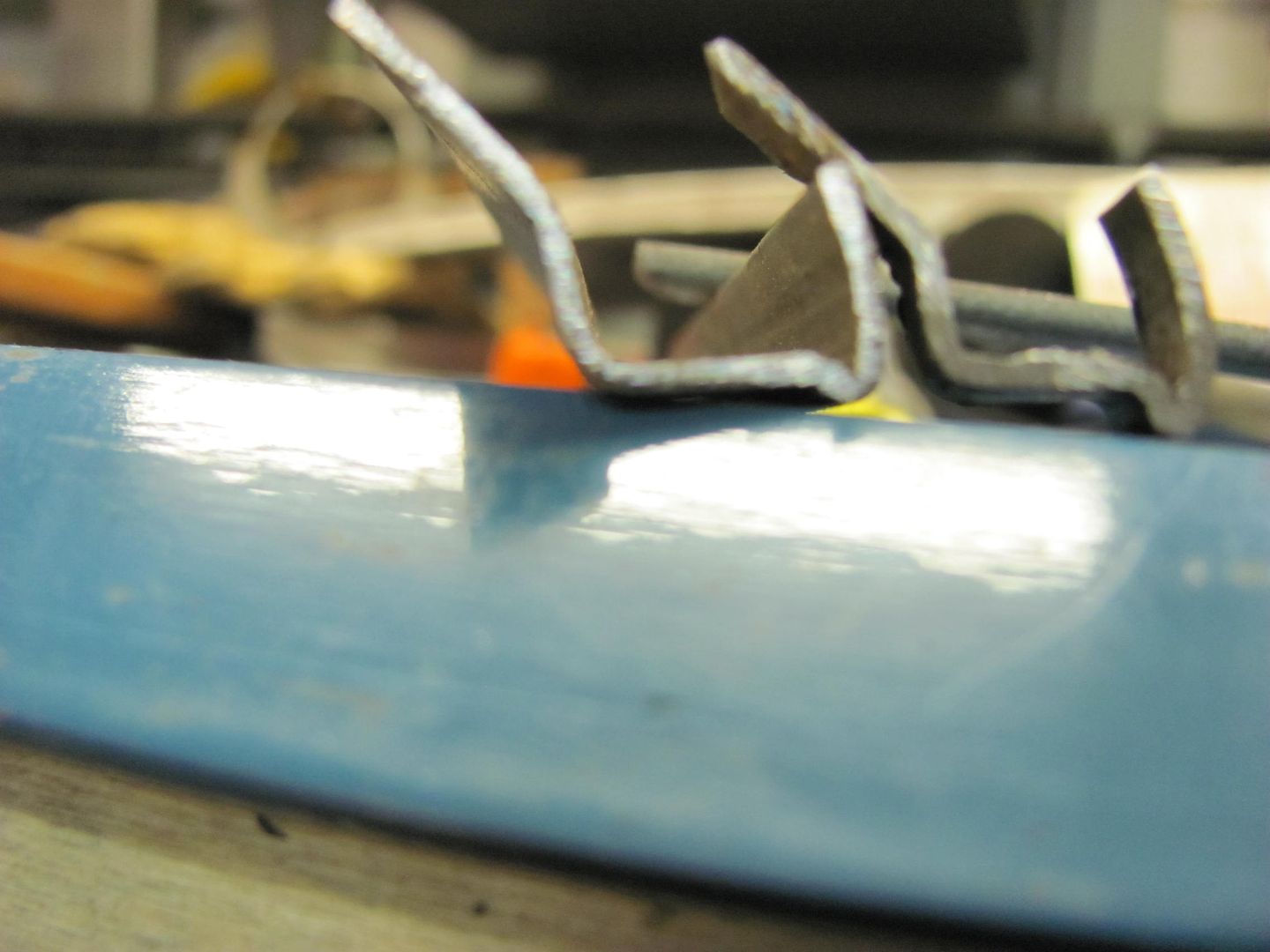

Missed a few of the other in-process pictures, but here is the "test sample"

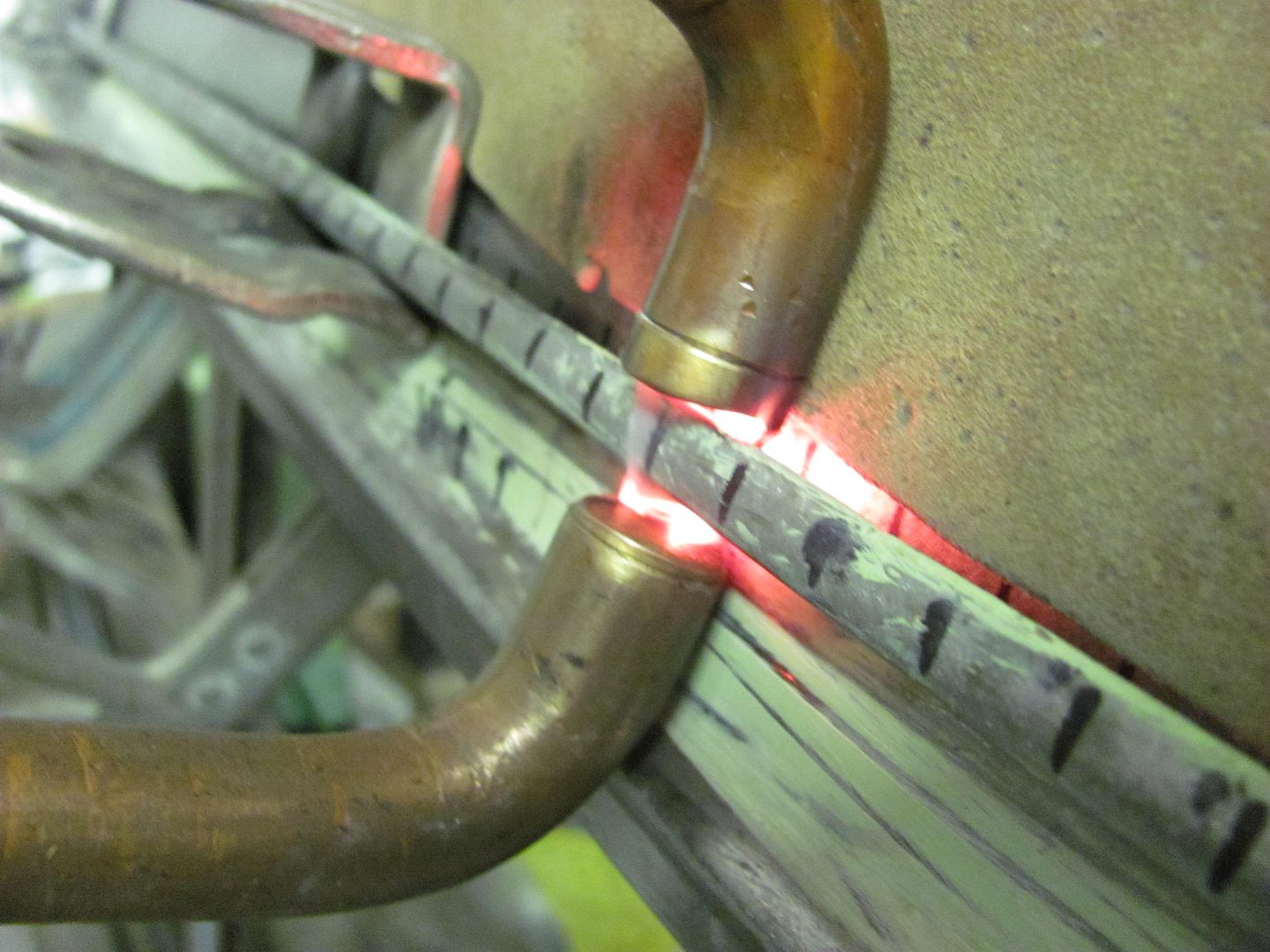

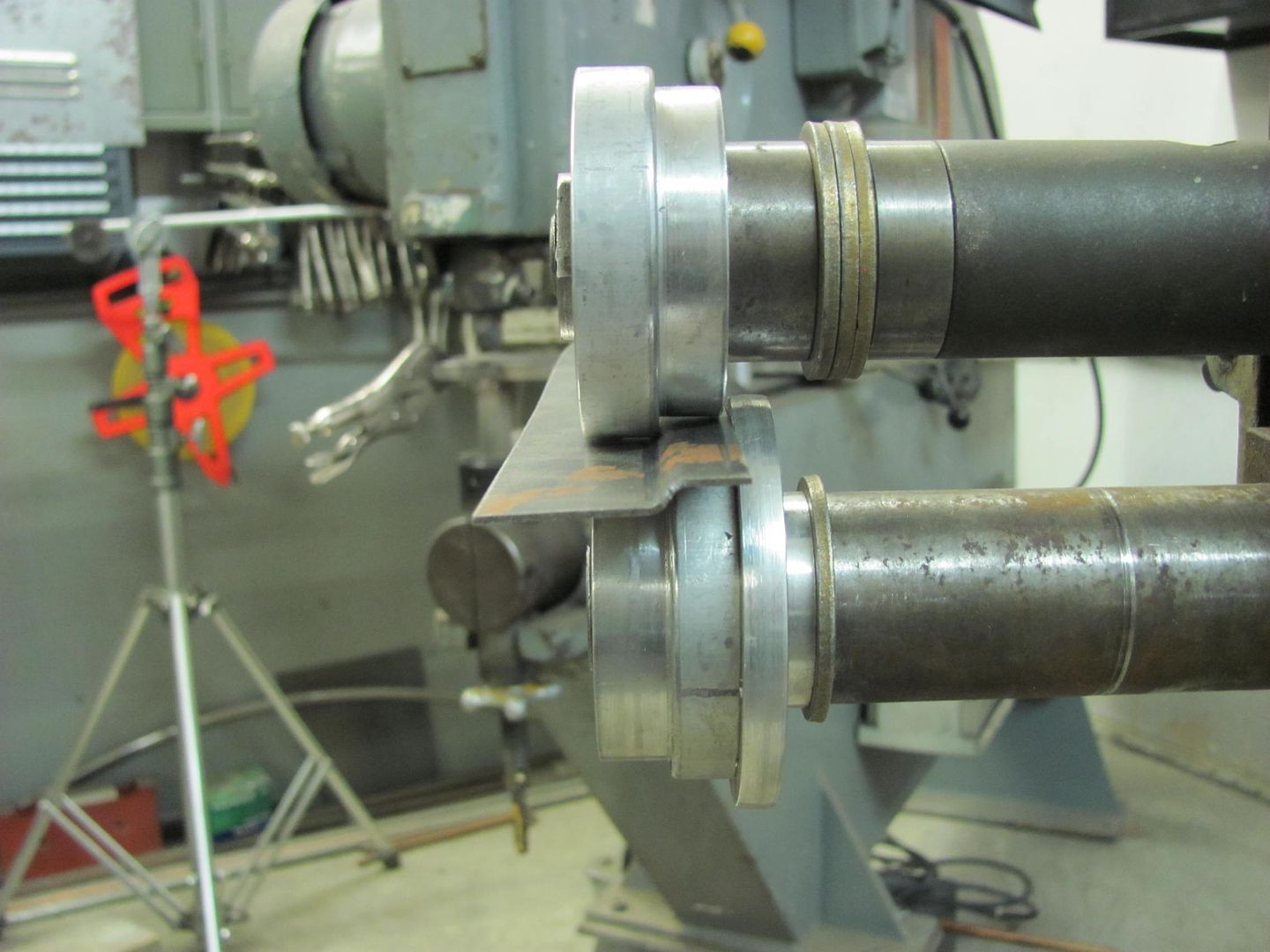

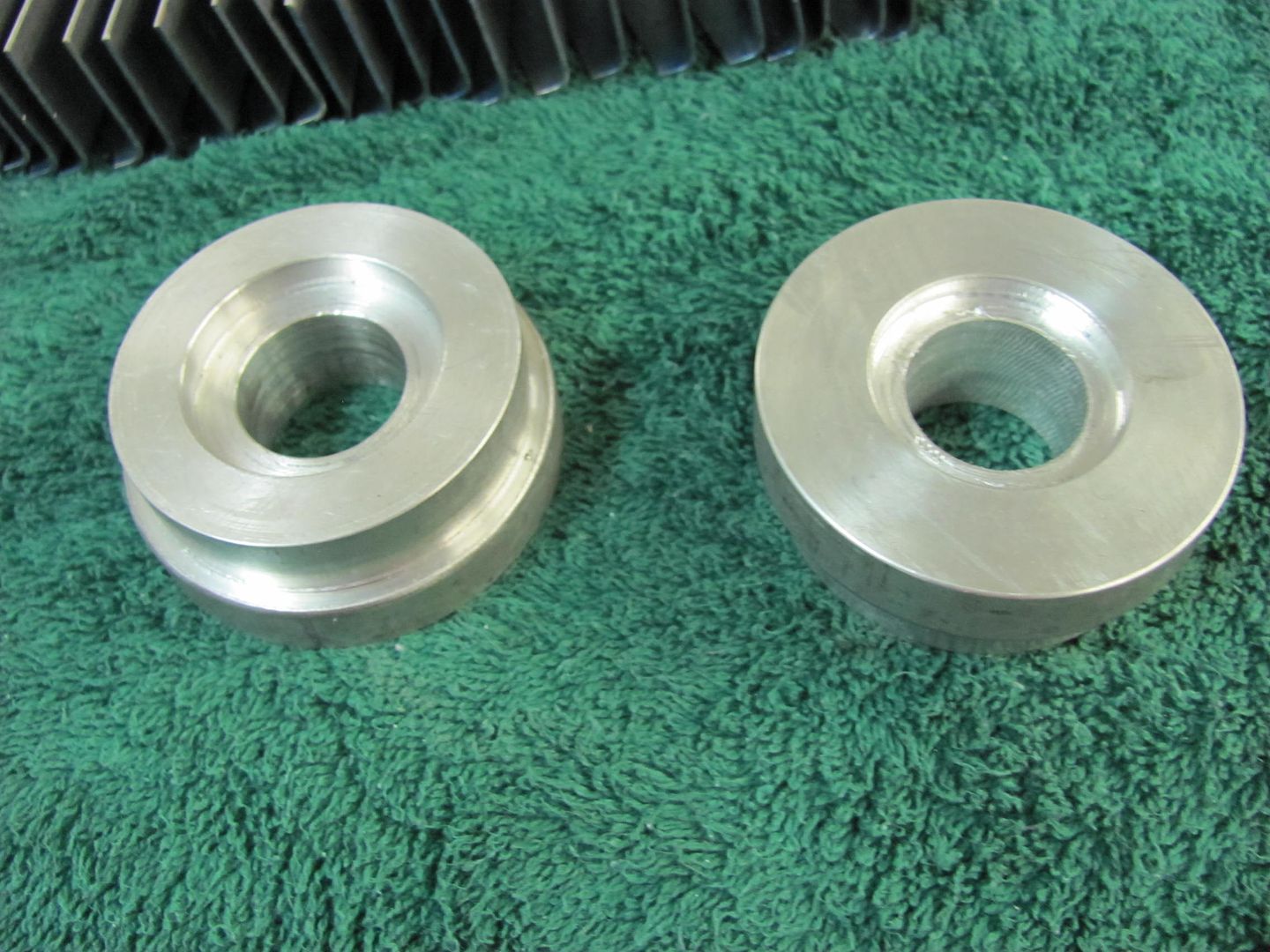

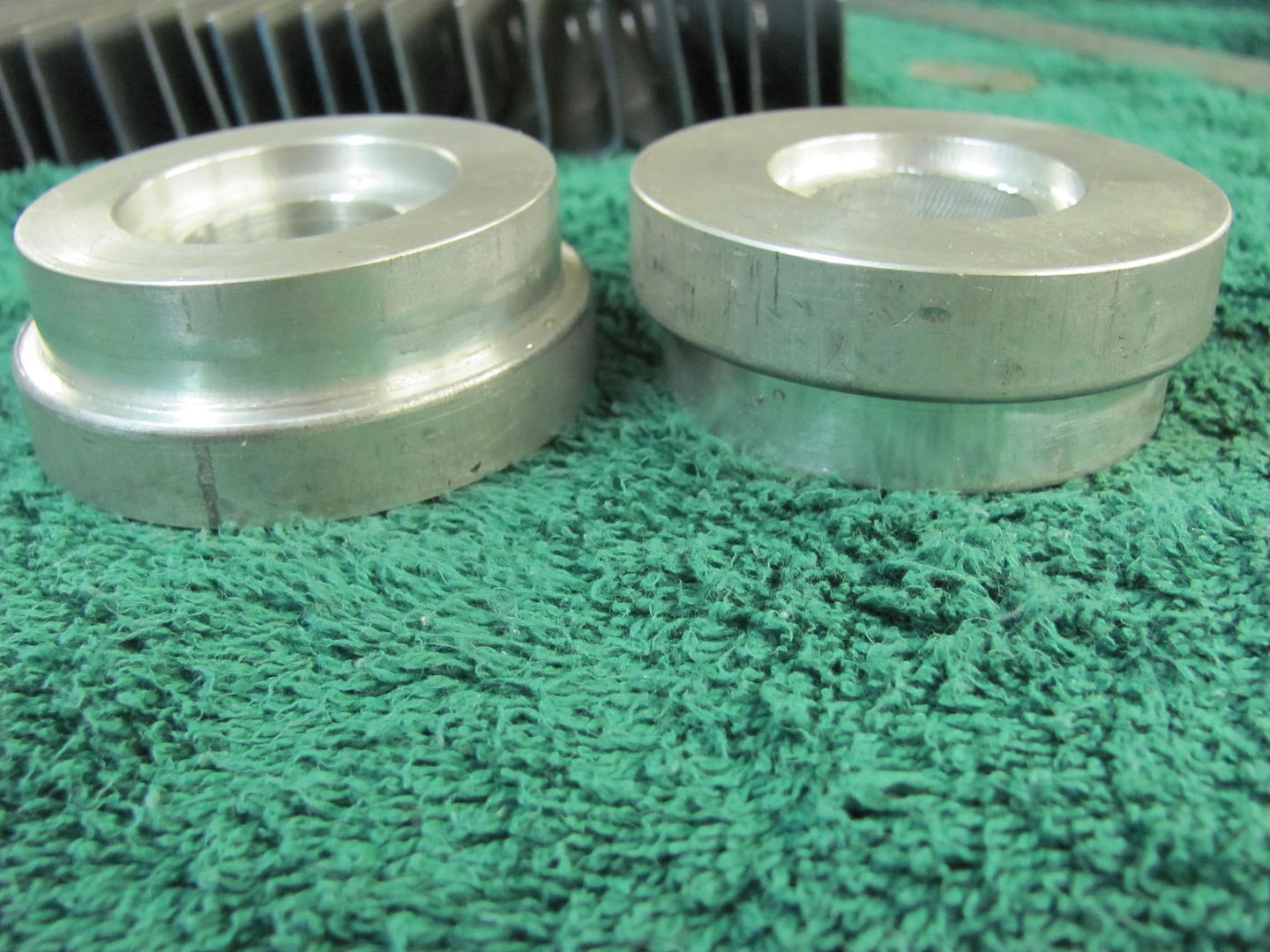

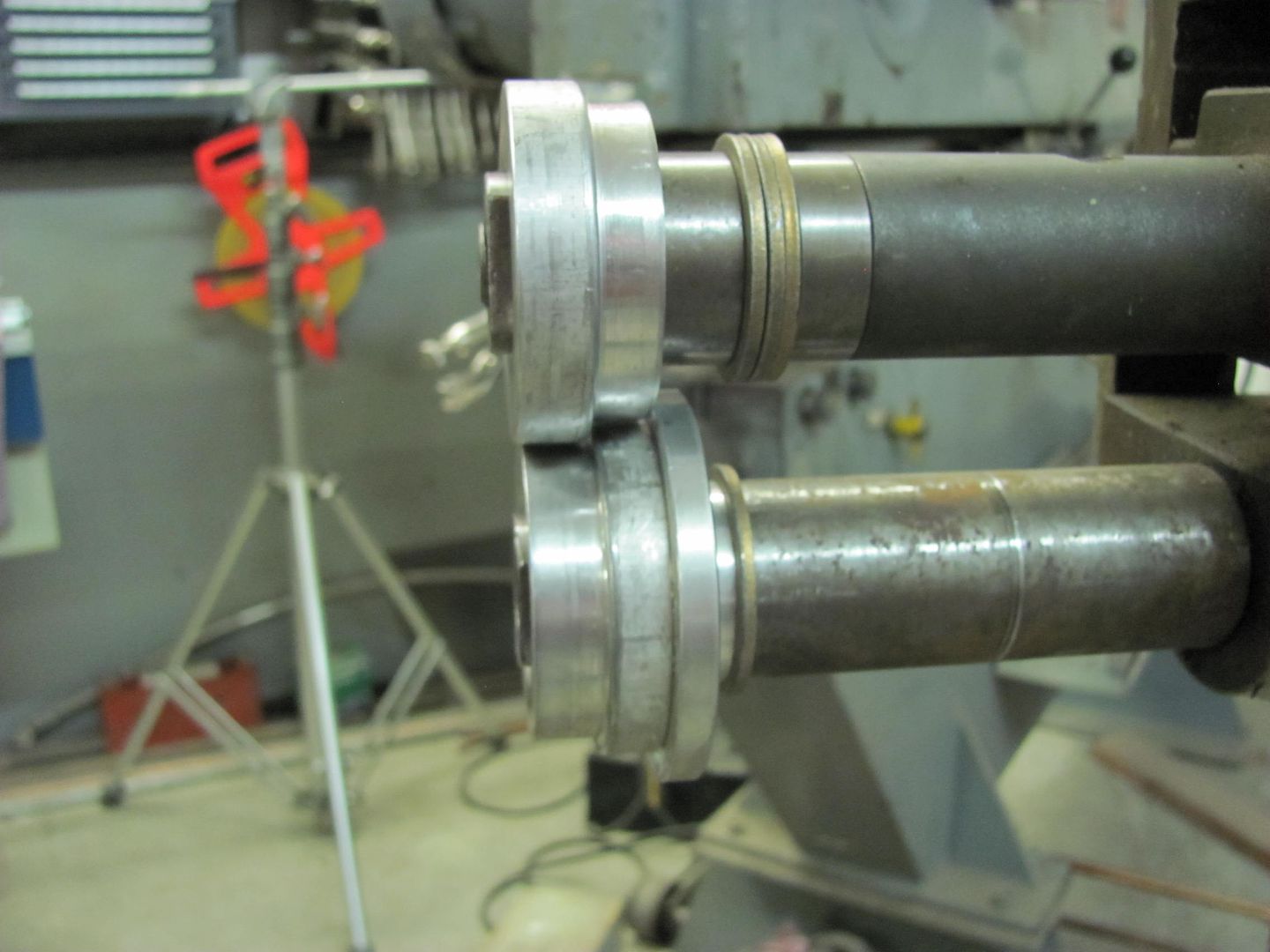

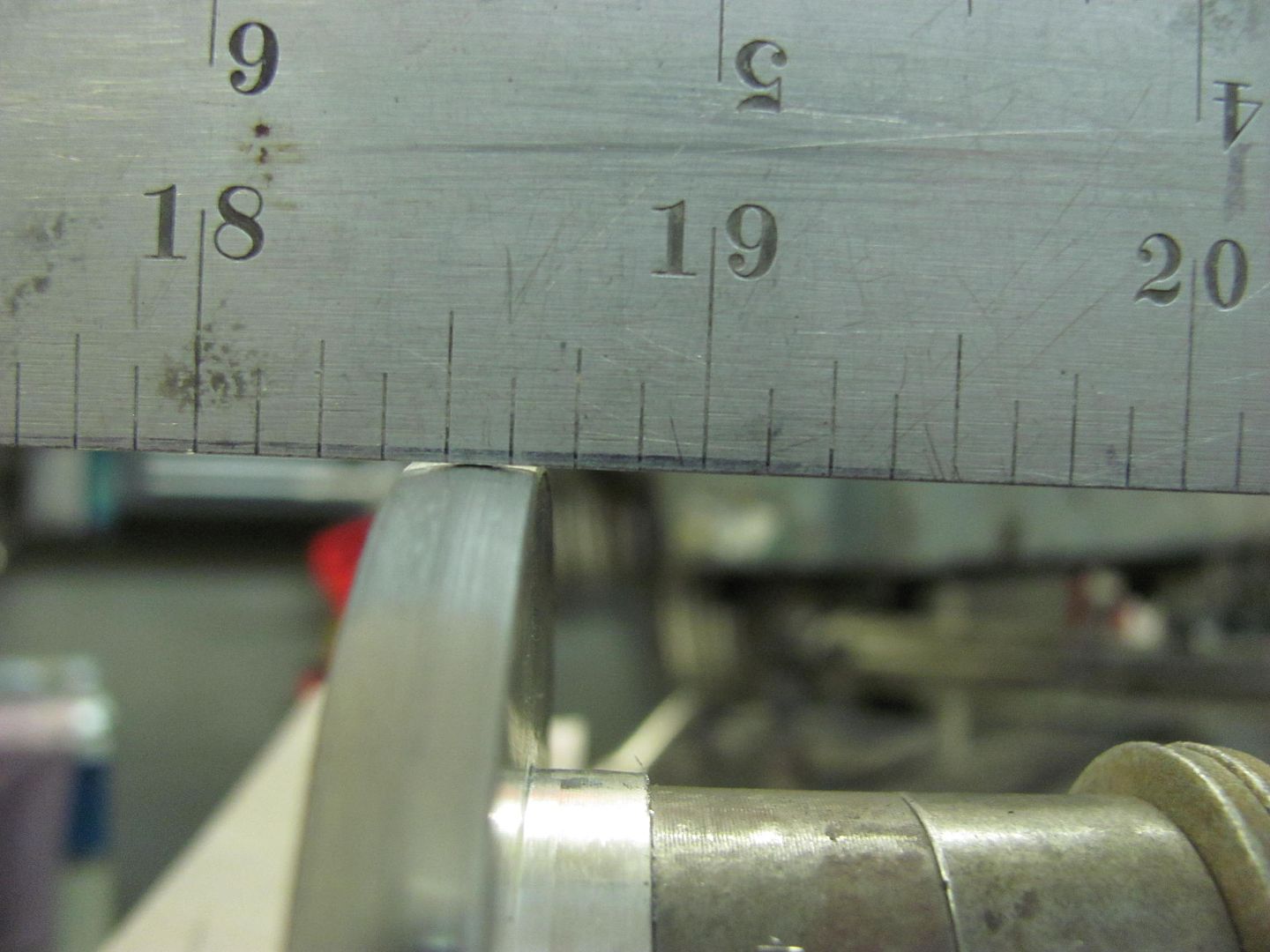

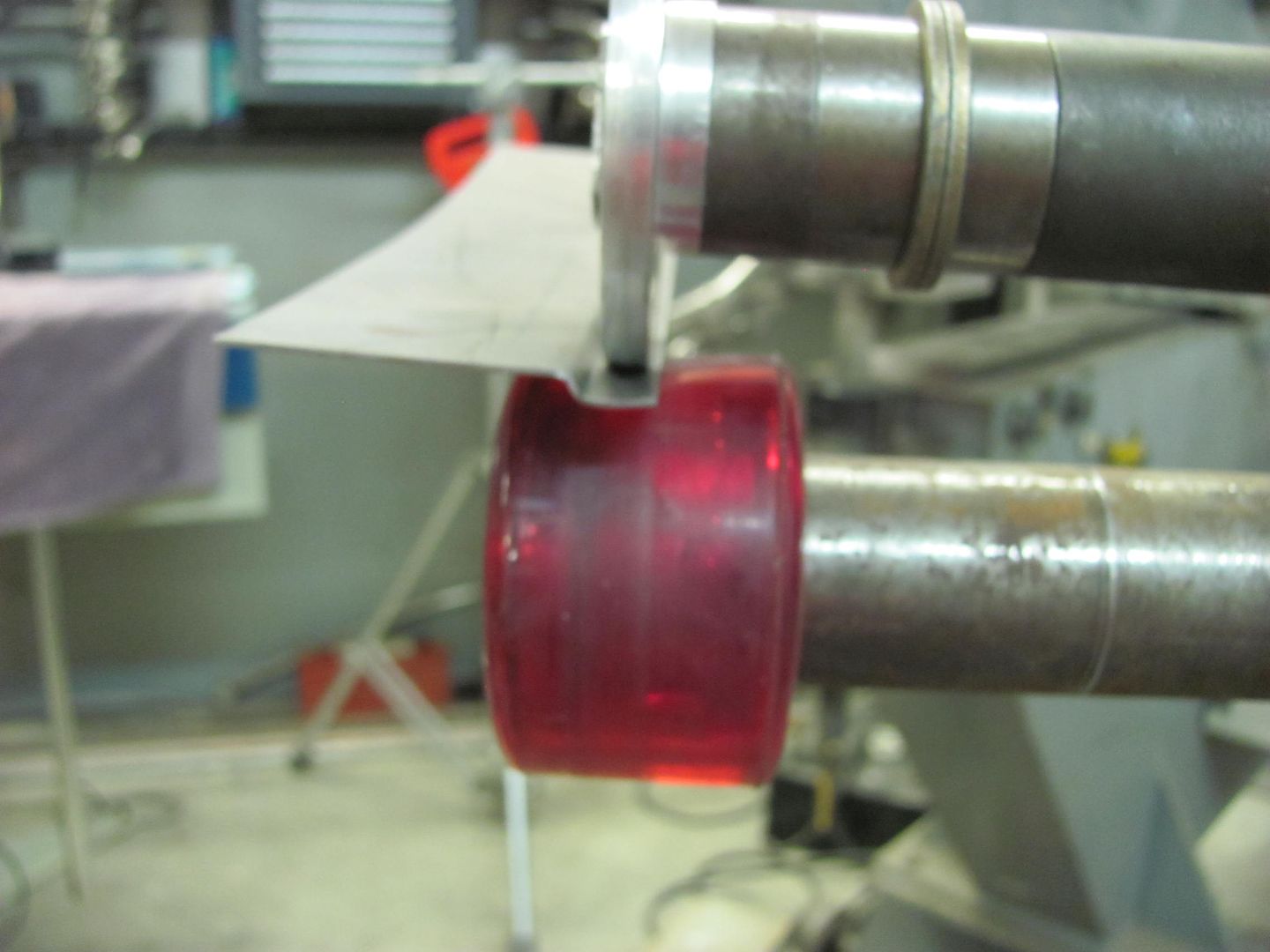

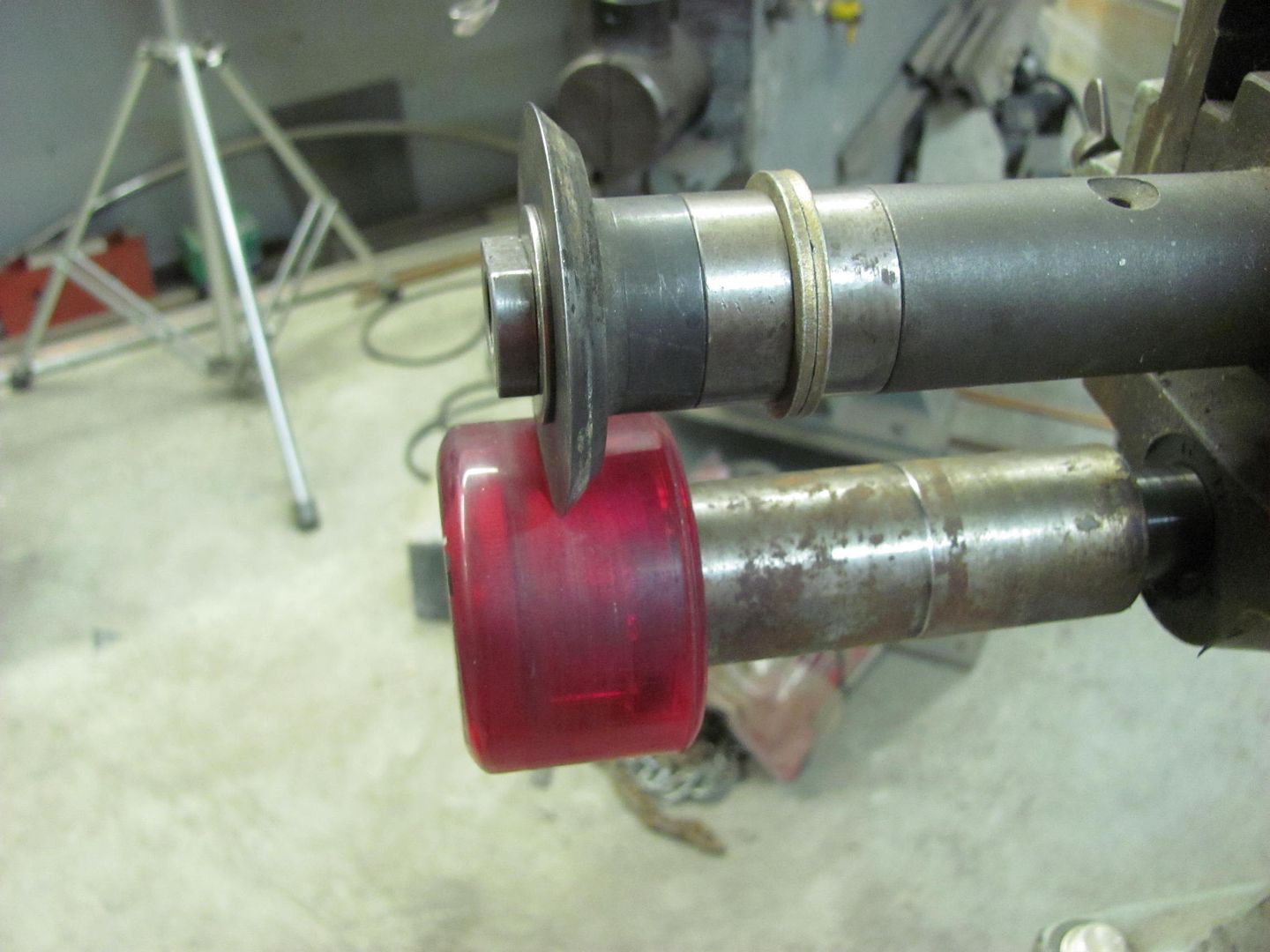

The resulting sample has the "drop" or offset from the bottom of the "tray" to the bottom of the outer face less in height than that on the original. Time to back up and punt.... The step dies in the bead roller are what is providing the offset height, so that needed to increase.. The dies I used in the original attempt had about a .07 offset. I didn't want to alter their size as they get used once in a blue moon for sheet metal offset, like I did for the 55 Chevy truck windshield panel.. So I decided to make another set, and based on the dimensional difference between the good sample and the trial piece, it looked like I needed to add about .04 to the offset, or .110 total. So here are the new dies that were formed on the South Bend..

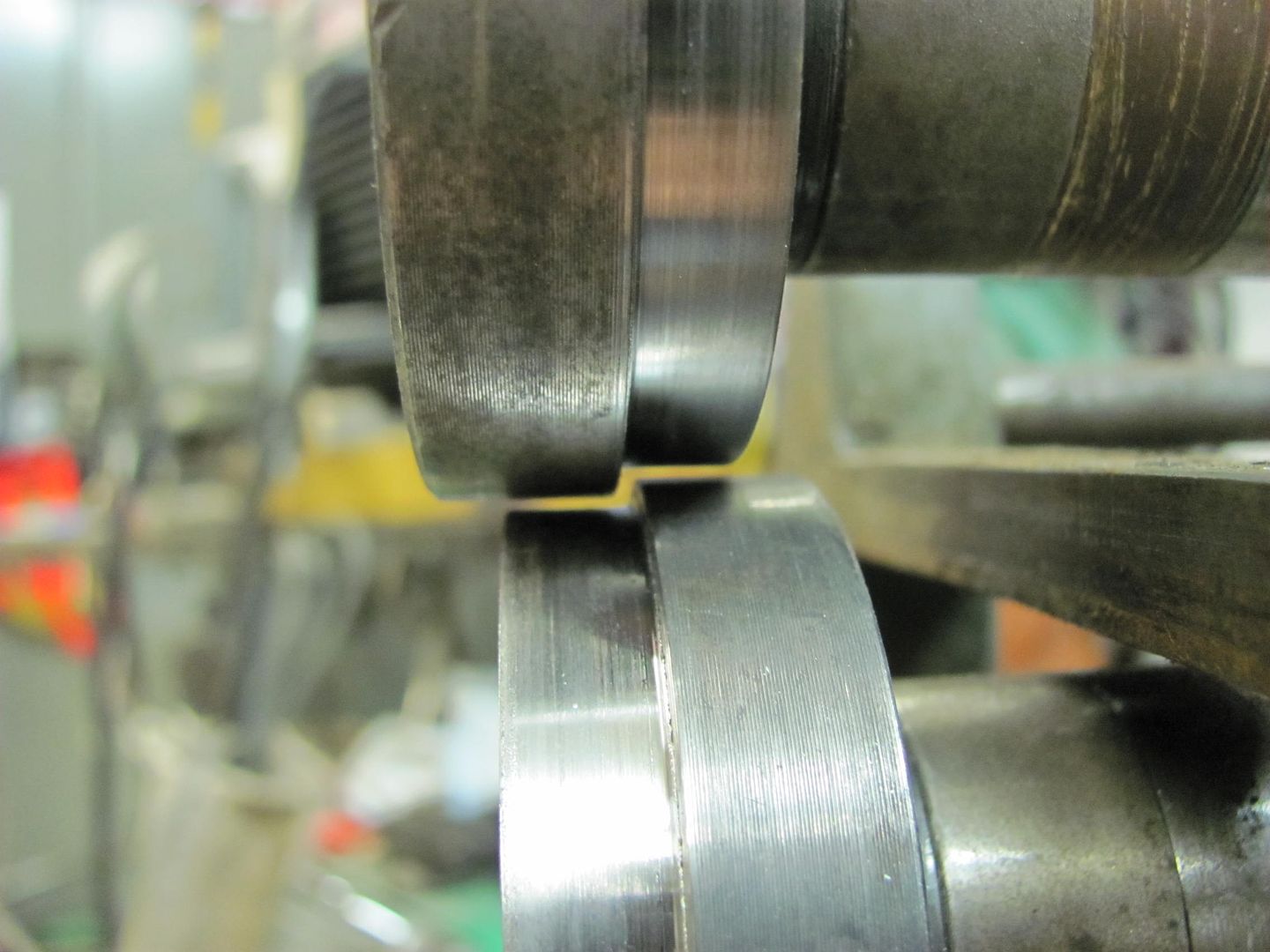

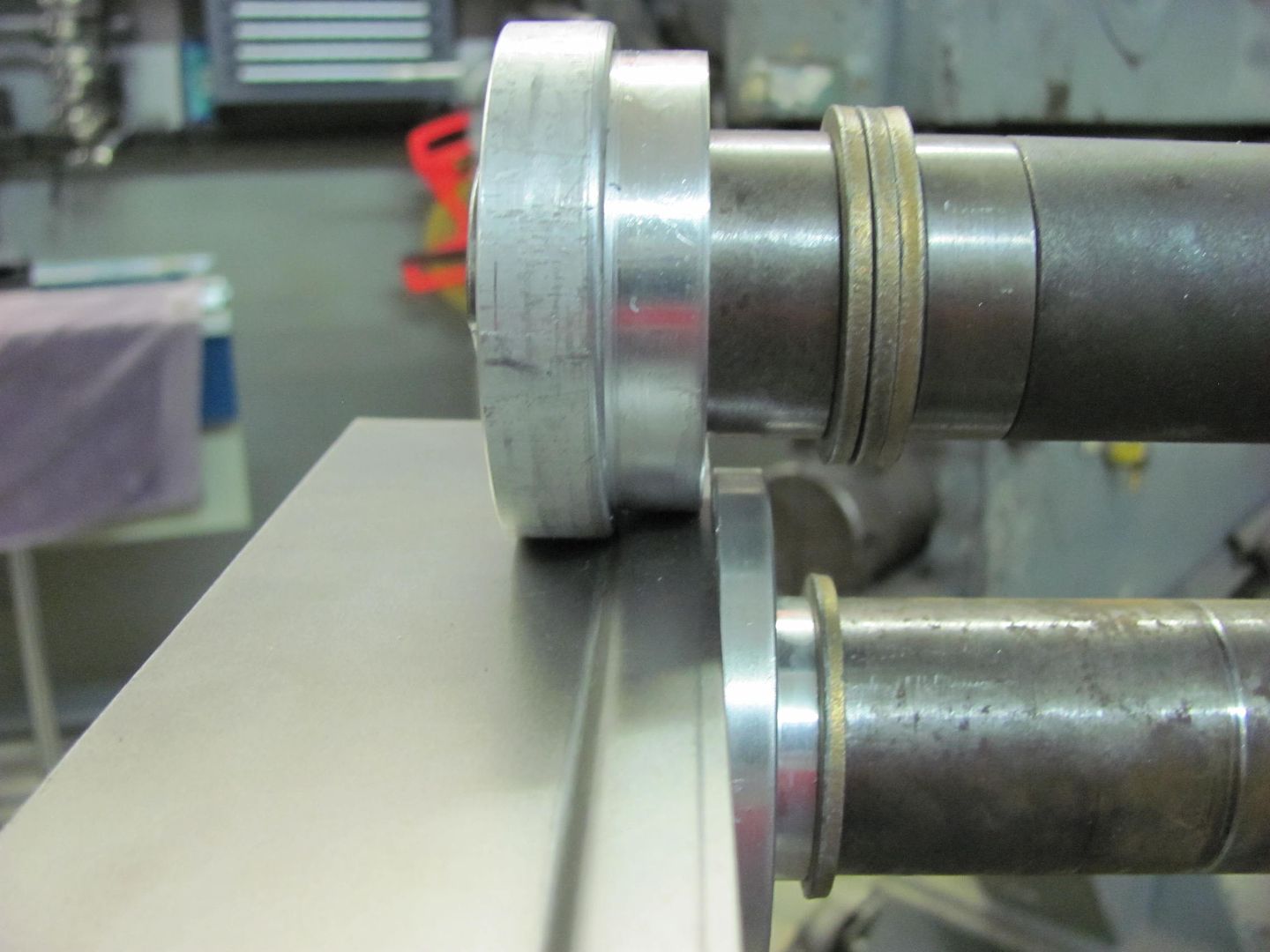

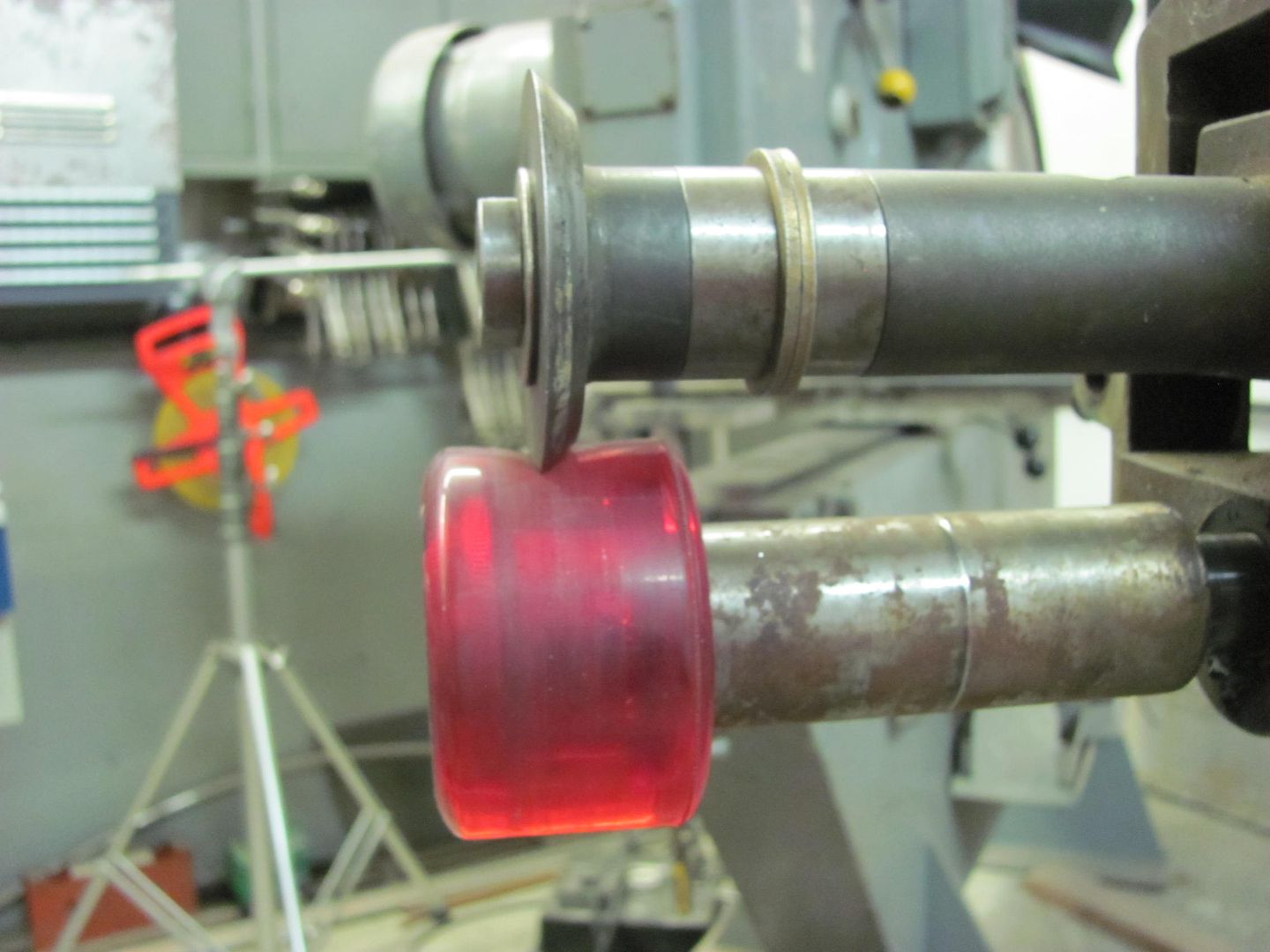

I used a "backstop" die behind the bottom roller, and after some trial and error, had to go back and trim a bit more off the width of the lower die to get the drip rail height correct.

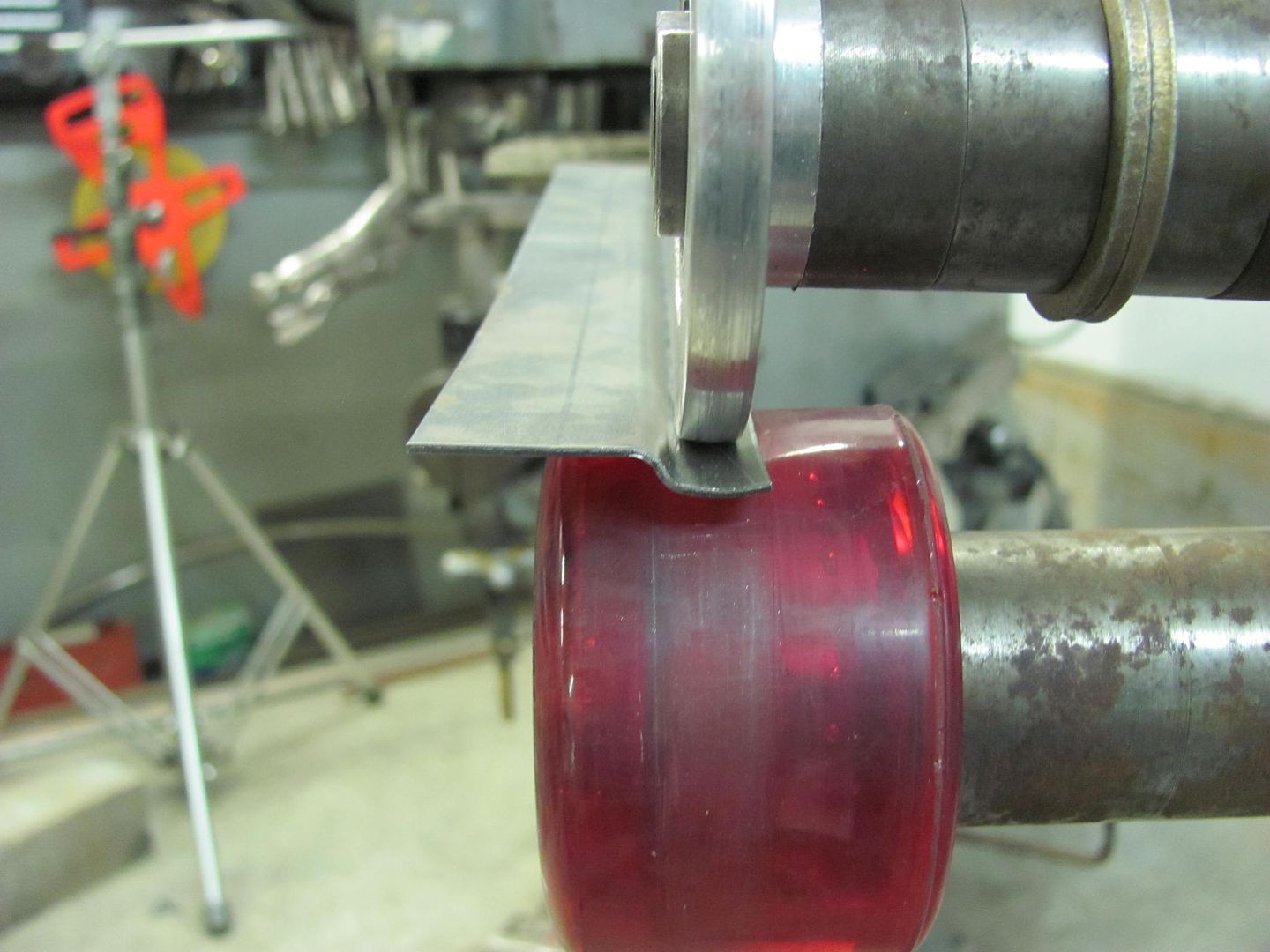

Then the "backstop" die was radiused to use with the skateboard wheel in providing the radius for the front face...

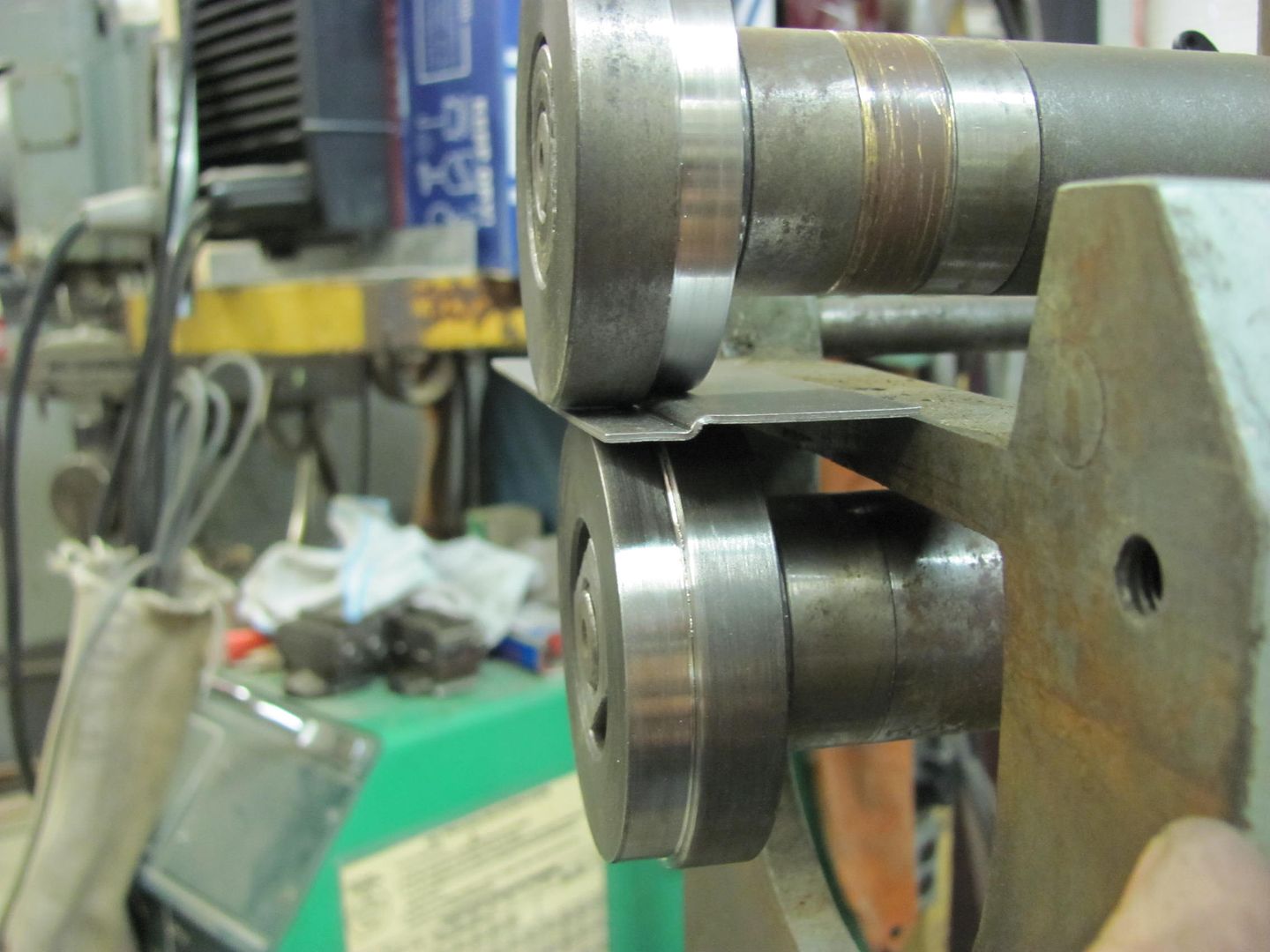

Then a few passes with the tipping die to fold up the front face...

The ends wanted to fold much more than the rest of the trial piece, so rather than continually readjust the tension, I sacrificed the first inch or so and just cut it off in the band saw.

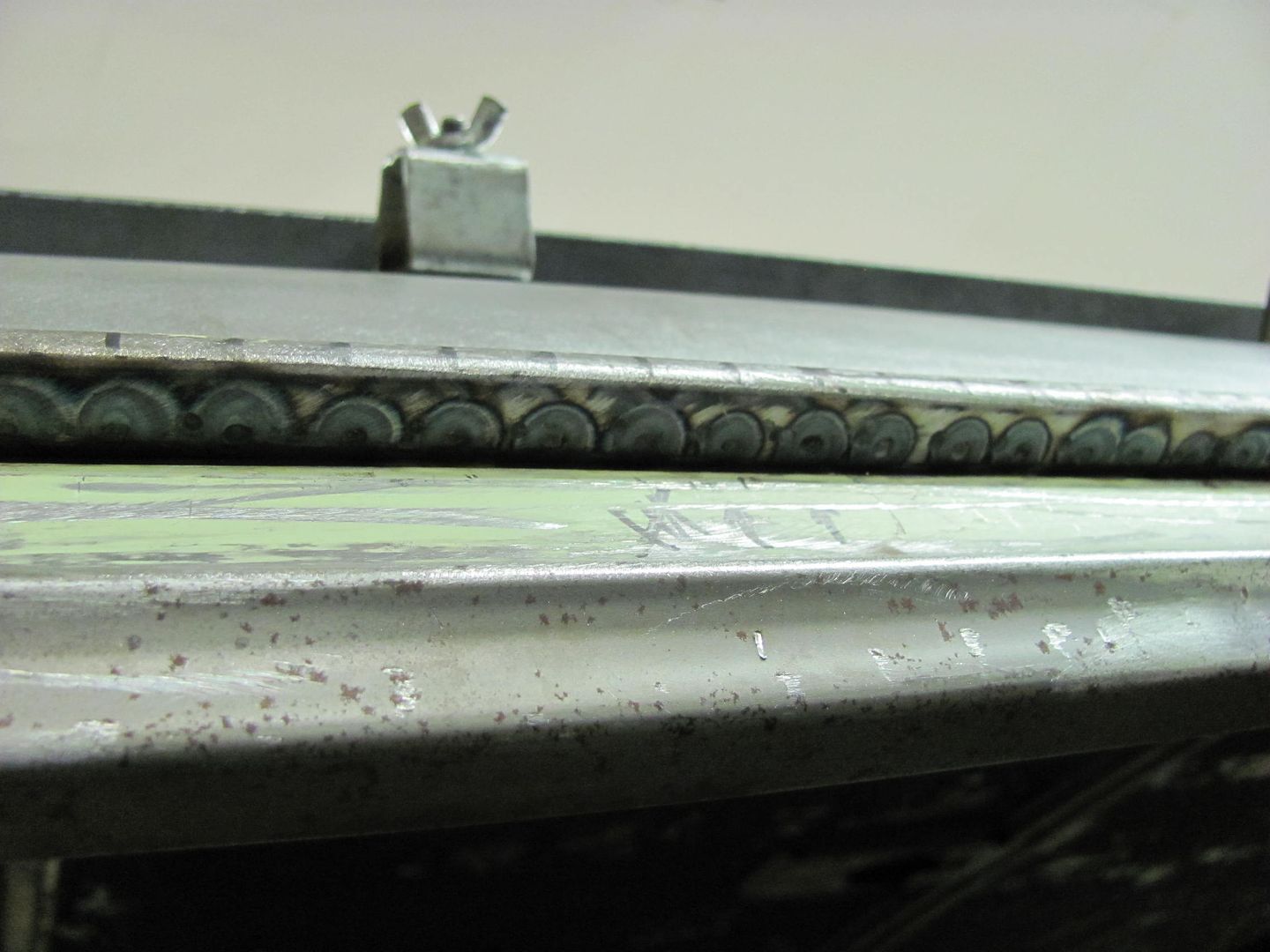

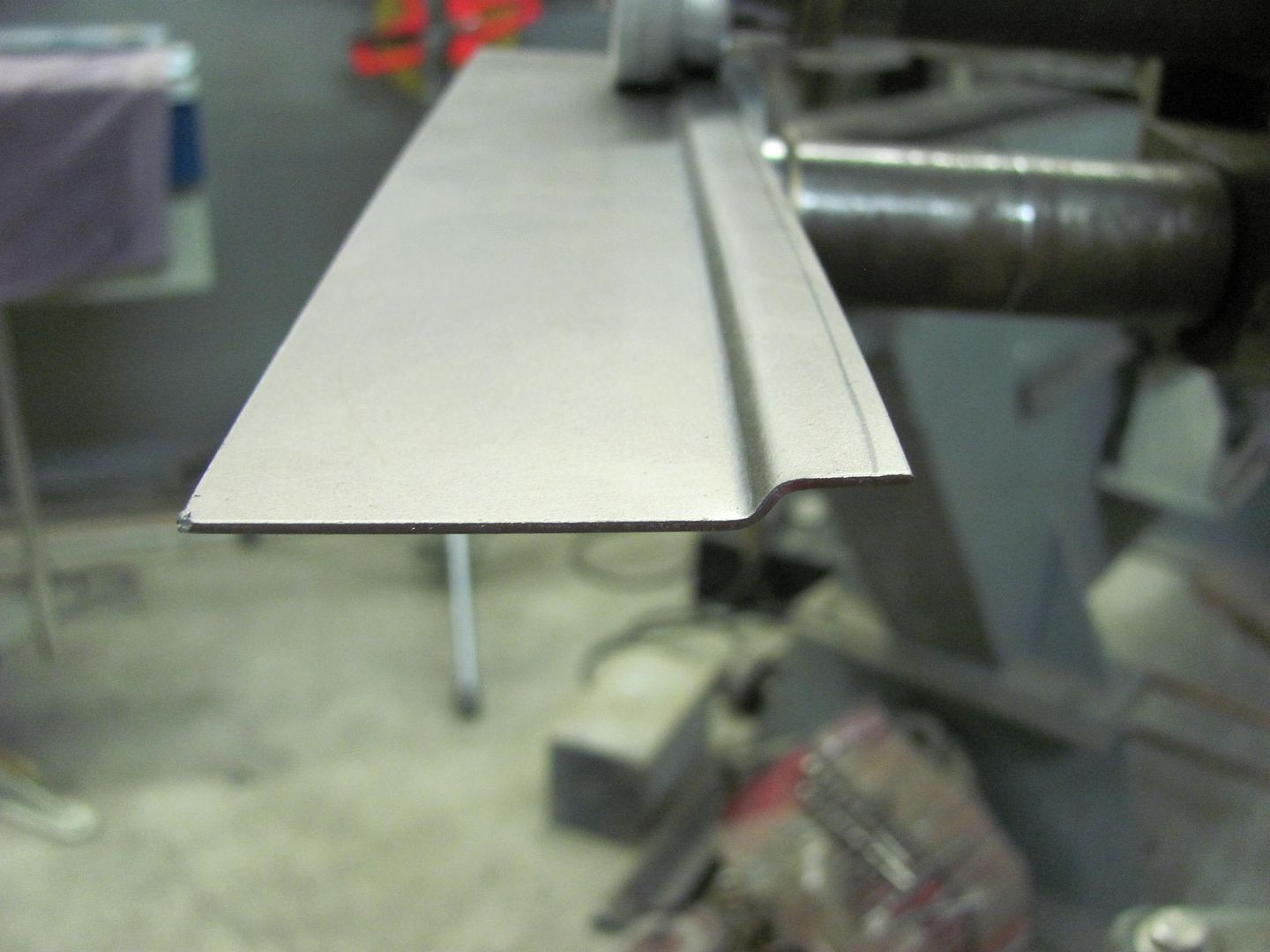

Here is the outer portion formed, the height of the face section is about perfect, this is using die width and back stop to regulate dimension...

The offset also turned out much better. The sharp bend (Vee shape at the bottom) on mine wasn't quite as tight together, but I don't know that I can get much better than that with this tooling I'm using, without changing to a different process (ie: more expense). For you Cherokee owners, before I proceed further, do you feel this slight variance in shape is "close enough"??