Page 1 of 3

The General

Posted: Sun Nov 06, 2016 6:19 pm

by ktrosper

I'm a bit intimidated by y'all's incredible builds and deep knowledge of the FSJ's.. I know mine isn't anything to write home about - but I love it!

Name: The General - Inspired by the paint job it had when I bought it. Sadly I had to paint over it for fear of being lynched by the neighbors!!

Acquired: Fall of 2013 - Yep! Poor things been waiting patiently for a little TLC..

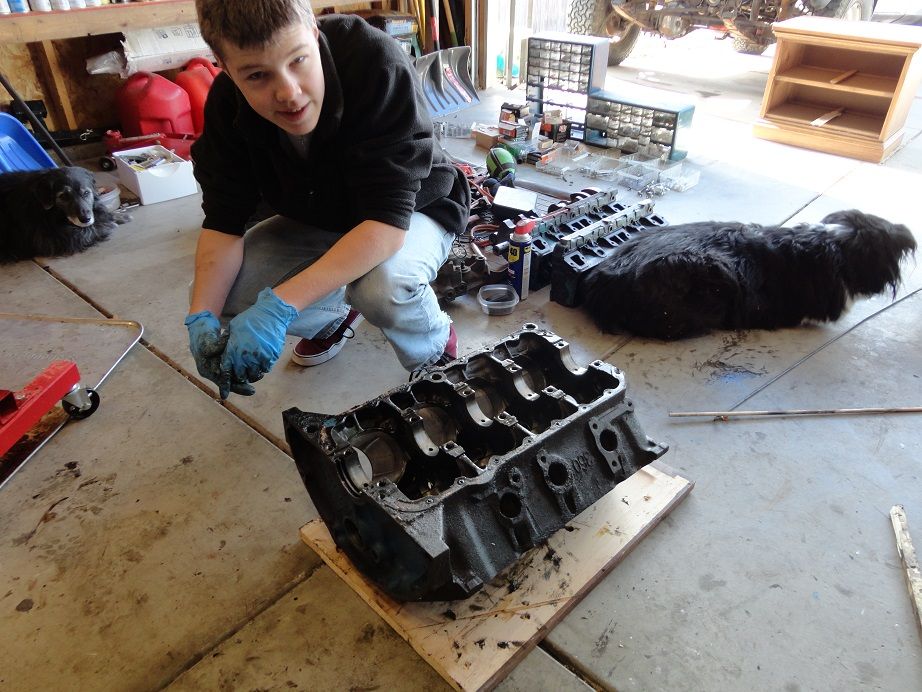

Build plan: Total restoration will have to wait.. For now, my 15 year old and I will be rebuilding the engine together to get it usable..

Use: Hunting truck, FWD & Camping truck, 2 day per week to/from work driver..

I'm pretty handy but I'd appreciate your input and advice as this project moves along.

Thanks,

Kelly

Re: The General

Posted: Sun Nov 06, 2016 7:07 pm

by Tatsadasayago

Nice looking J-Truck!

Welcome to the network/madness

Re: The General

Posted: Mon Nov 07, 2016 8:55 am

by ktrosper

No turning back now, eh?

That's 37 years of dirt and grime..

Disassembly and inspection begins tonight

Re: The General

Posted: Mon Nov 07, 2016 9:37 am

by REDONE

Woohoo! Looks like fun and you're in a great place to be rebuilding an FSJ. Blake is just in Longmont (his J-10 is famous, he did the Petersons Ultimate Adventure a few years ago), and down here in Denver there's a bunch more of us that get together from time to time for grilling, wrenching, and lying about things we've seen or done. Hope to see you and the General soon!

Re: The General

Posted: Mon Nov 07, 2016 3:23 pm

by Nikkormat

Yeah! Get that thing done for Moab in the spring!

Re: The General

Posted: Mon Nov 07, 2016 8:55 pm

by twisted frame

Very good looking truck! I can't tell from the photo but are those the older Selectro front hubs?

Re: The General

Posted: Tue Nov 08, 2016 7:16 am

by REDONE

twisted frame wrote:Very good looking truck! I can't tell from the photo but are those the older Selectro front hubs?

I'm pretty sure they're just the regular slugs since it's a Quadratrac rig.

Re: The General

Posted: Tue Nov 08, 2016 8:11 am

by Skerrvydog

ktrosper wrote:I'm a bit intimidated by y'all's incredible builds and deep knowledge of the FSJ's.. I know mine isn't anything to write home about - but I love it!

Name: The General - Inspired by the paint job it had when I bought it. Sadly I had to paint over it for fear of being lynched by the neighbors!!

Acquired: Fall of 2013 - Yep! Poor things been waiting patiently for a little TLC..

Build plan: Total restoration will have to wait.. For now, my 15 year old and I will be rebuilding the engine together to get it usable..

Use: Hunting truck, FWD & Camping truck, 2 day per week to/from work driver..

I'm pretty handy but I'd appreciate your input and advice as this project moves along.

Thanks,

Kelly

I recently met a guy around the corner from me with a 70 something Cherk, with real General Lee air horns in the bay. Always gives me a toot when he drives by!

Re: The General

Posted: Tue Nov 08, 2016 3:10 pm

by az chip

Nice truck! You are on your way.

Re: The General

Posted: Tue Nov 08, 2016 4:51 pm

by BRUTUS

I would love to stop by sometime and check out the progress.

I love the old paintjob!

Re: The General

Posted: Sat Nov 12, 2016 6:09 am

by ktrosper

Thanks guys

Glad to know some of you are in the area. Looking forward to meeting you and picking your brains for sure.

We made some nice progress this week, albeit slow. Making sure the boy is involved in every step and homework trumps truck work

We've stripped most of the accessories off at this point.

Removed the boat anchor that is the cast intake - HOLY S#!% that was heavy!

Removed the heads..

Re: The General

Posted: Sat Nov 19, 2016 2:04 pm

by ktrosper

Re: The General

Posted: Sat Nov 26, 2016 6:03 pm

by ktrosper

Heading to the machine shop Monday with the heavy stuff

So they'll need the block, crankshaft, pistons/connecting rods, heads and valves (cam, lifter, rockers, springs and push rods will be replaced).. Right? With that we can determine what machining must take place and what needs replaced?

If I have the heads decked/shaved to up the compression a bit, will that change the geometry of the intake to the extent that it'll need machined also? Should I bring the intake in as well?

Regarding the engine build.

My plan is basically "stock plus".. I want low RPM torque and I'll consider big "bang for the buck" upgrades that make sense and are easy to maintain. I'm a big fan of K.I.S.S. I'll eventually lift it and spin 35's or 36's- so some axle ratio work is probably in my future. Right now I'll keep the 33's and 3.73's.

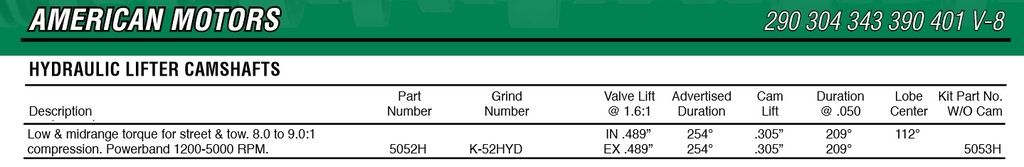

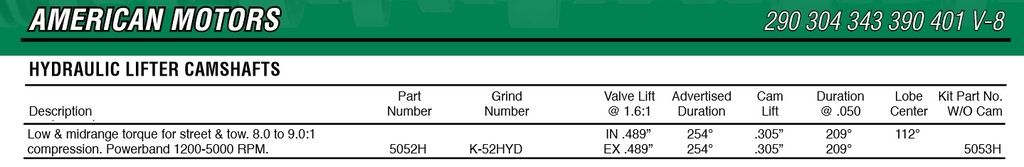

I've settled on an Engle 5052H cam:

Should do fine for what I'm after..

I'll be swapping out the 2bbl (MC2100 or 2150??) to a 4bbl Quadrajet.. Why? It fits my "bag for the buck" principle I guess because I found the 4bbl spread bore intake in the bed of the truck and my reading suggests that upgrading from 2bbl to 4bbl give you a nice power boost on this 360... Can't afford a TBI and would prefer not to drop several hundred dollars on a performer intake/holley..

I'll put the iron manifolds back on. Sounds like they flow nicely and will be fine for this build.

See that part at the base of the passenger side manifold? The bolts at the pipe flange were frozen hard core when the boy and I yanked the engine so we unbolted it at the heads and just left it.. I finally got around to working the thing free today and notice a strange part on the end of it between the manifold and the pipe...

Closer examination revealed a spring actuated butterfly valve.

HAH! Is this some kind of trick used to pass emissions? Would it essentially cut emissions in half when it's closed?

Too funny.. It won't be going back on but I got a laugh outta that.

Re: The General

Posted: Sat Nov 26, 2016 6:13 pm

by Nikkormat

Bad news friend, that manifold won't accept a quadrajet. It's a different spread bore. A MC4350.

I've got the carb you need. PM me.

Re: The General

Posted: Sat Nov 26, 2016 6:43 pm

by ktrosper

Oh crap. Ok well cool.. That's exactly why I'm tossing this out to you guys. You know you're stuff

Thanks for the deal on the carb, Nik.

"While the engine is out..." Five evil words that I'm sure y'all have uttered a time or two

Heh. Lot of work needs to be done up front (and in the rear I'm sure) and I figure I may as well get to it while the engine out. My wife came home and saw the front of the truck missing and just shook her head

Looks like the driver side springs are toast, held together with make shift brackets and a bit twisted/bent. Can I replace just that side and keep the others or is it a good idea to replace both?

http://www.bjsoffroad.com/Stock-Height- ... _1332.html

The axle is a gunked up mess. This truck was being driven daily when I bought it. Can I assume the axle is healthy and simply needs seals?

Re: The General

Posted: Mon Nov 28, 2016 8:05 pm

by ktrosper

Regarding this D44 front axle.. Is there a seal kit that'll let me seal it up if I assume the bearings are good? Or do I want to throw new bearings in there while I'm replacing seals? What would you guys do?

Re: The General

Posted: Mon Nov 28, 2016 8:41 pm

by REDONE

ktrosper wrote:Regarding this D44 front axle.. Is there a seal kit that'll let me seal it up if I assume the bearings are good? Or do I want to throw new bearings in there while I'm replacing seals? What would you guys do?

I reuse carrier bearings all the time. If they're good and tight when you pop the carrier out to replace the seals I'd reuse them. It's been my experience that the seals usually go bad when installing the axle shafts, either ripping the lip of the seal or the shaft is nicked or picks up crud in the tube wrecking the seal in short order.

If you're replacing the pinion seal, I recommend removing the pinion nut first thing. It's so much easier when you can jam pry bars in the knuckle ujoints and reef on it. If you reuse the bearings and shims on the carrier and pinion you don't have to worry about setting up the gears: saves a ton of hassle.

Re: The General

Posted: Mon Nov 28, 2016 8:54 pm

by ktrosper

Thank you very much Redone

Re: The General

Posted: Wed Nov 30, 2016 5:58 am

by ktrosper

Disassembled engine is at the machine shop and axle seals, including thrust washers, are on the way.. I ordered a seal kit for the tranny and transfer case - file that under the "while I'm at it" heading. Getting my pressure washer back from the B.I.L. later this week and I'm looking forward cleaning this sludge off of these things. Seems I'm doing a whole lot of tearing down but these project always seem to get worse before they get better, eh?

Re: The General

Posted: Sat Jan 21, 2017 7:15 pm

by ktrosper

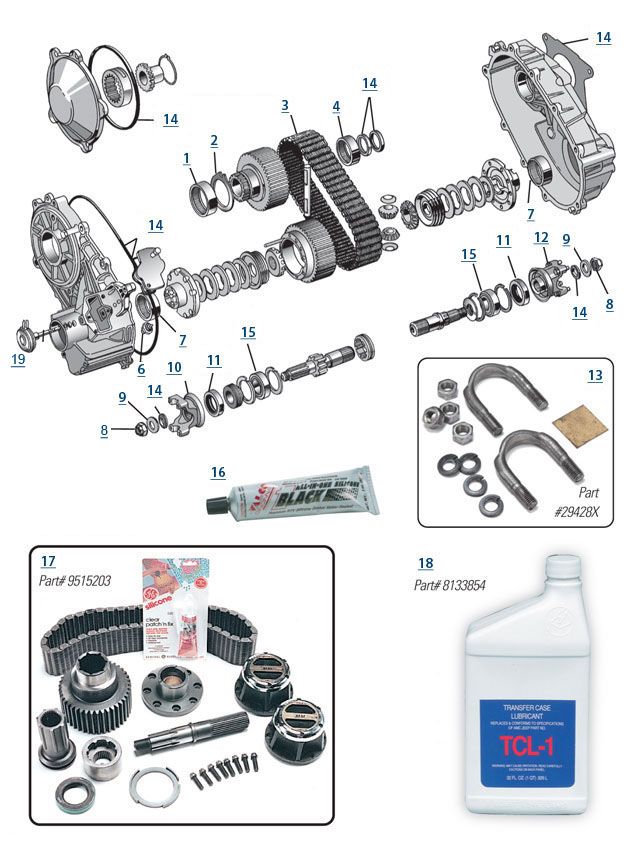

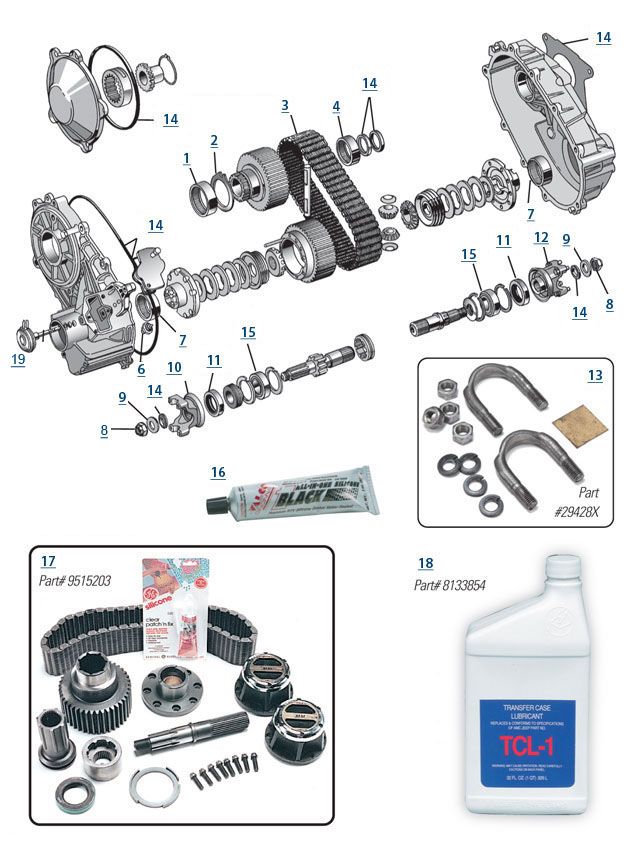

BW 1339 QuadraTrac teardown and inspection

Yay! Powerwasher!

Cleaned up and tore down the BW 1339 QuadraTrac.. I knew I had some seals leaking and I think I could have changed them without a total teardown but I wanted to make sure everything in there was healthy. I don't want to assume anything at this point..

Thought I drained it pretty good but there was still enough oil in there to make a helluva mess

Here's the "Oh Crap!" stuff I found floating around in the case..

Cleaned everything up so I could get a better look at the damage..

Most of the metal chunks were remnants of the gear that used to live at the end of the differential end cap. I think it was the Edrive gear?

Those chunks were sequestered to the Edrive lever housing area between the 2 output shaft bearings (one is the needle roller bearing the other is the annular output shaft bearing). I think that probably saved the entire thing from grenading. Had those chunks of gear metal not been stuck between those bearings, they'd have been free to tear up any number of things in the main case area..

Here's a look at some of the damage in that Edrive housing area.

Needle rollers all fell away as soon as the shaft was removed... The annular output bearing is gored up a bit and wasn't spinning smoothly.. The case was a marred a bit but nothing too deep that would concern me.

So.. I've already replaced the sprocket bearing (needle roller bearing). I can NOT find the annular bearing anywhere. I don't think I can find a new one at this point so I'm pretty sure I'll need to find a donor or hope to buy one off of one of you guys..

I'm also not sure what to do about the endcap.

a. grind it smooth and say F-It and roll without Edrive capability? (how often do y'all use it?)

b. buy a used one off ebay or find a donor and get it functional...

parts drawing:

So here she sits, partially assembled on the shelf til I figure out what to do..