Torque specs on the oil pan and rod/main bearing caps ?

-

candymancan

Topic author - Posts: 3684

- Joined: Tue Mar 22, 2016 11:32 pm

Torque specs on the oil pan and rod/main bearing caps ?

Finally my standard size rod bearing is coming friday, only took teamgrandwagoneer 2 weeks to mail it out. So everything is ready to drop the oil pan and replace that horrible rear main seal, and inspect the rod 8 bearings since i have a knock coming from there. Im hoping if its the rod the crank will be fine and i can just replace the bearing. But i made a thread about that a week ago.

My question in this thread is whats the torque for the oil pan bolts, can i use RTV like THE RIGHT STUFF or should i get a felpro gasket, tbh i like rtv but yea.. The Main bearing cap where the rear main seal is on, and also the rod bearing cap what are the torque specs ?. Is it a set torque. or is it one of those torque specs with a 90 degree turn after kind of torque ? And whats an easy way to turn the engine by hand so i can get easier access to rod 8 if it isnt there for me when i drop the pan.

My question in this thread is whats the torque for the oil pan bolts, can i use RTV like THE RIGHT STUFF or should i get a felpro gasket, tbh i like rtv but yea.. The Main bearing cap where the rear main seal is on, and also the rod bearing cap what are the torque specs ?. Is it a set torque. or is it one of those torque specs with a 90 degree turn after kind of torque ? And whats an easy way to turn the engine by hand so i can get easier access to rod 8 if it isnt there for me when i drop the pan.

1998 Jeep Grand Cherokee 5.9L Limited 219k

1998 Jeep Grand Cherokee 4.0 I6 laredo 430k

1990 Jeep Grand Wagoneer 155k

1976 Jeep J10.. 85k(repaired)

1998 Jeep Grand Cherokee 4.0 I6 laredo 430k

1990 Jeep Grand Wagoneer 155k

1976 Jeep J10.. 85k(repaired)

-

Tatsadasayago

- Posts: 3684

- Joined: Thu Aug 28, 2014 2:22 pm

- Location: Sacramento, CA

Re: Torque specs on the oil pan and rod/main bearing caps ?

Your rear main bearing cap dry torque should be 100 foot pounds.

Your rod cap nuts should have a dry torque level of 33 Foot Pounds.

The oil pan bolts should be 7 Ft. Lbs with a dry cork or synthetic gasket but if you use sealants with or without the gasket then you need to employ the 'squish' method. In this case you apply the gasket and tighten the bolts until you see the gasket and/or sealant begin to ooze out from the gap. This is often an intuitive thing as the various combinations of gaskets or sealants will act differently.

On AMC V-8s I prefer to use a cork gasket along with a thin layer of RTV and tighten until I see the RTV begin to ooze out between the pan and block. The longer you allow the RTV to set up the better the squish factor.

Also, when you install the rear main seal, instead of aligning the ends of the seal with the block/cap, rotate it a bit farther until a 1/4" to 5/16" of one end is protruding. This removes the seal ends from the cap/block joint and adds additional sealing.

Your rod cap nuts should have a dry torque level of 33 Foot Pounds.

The oil pan bolts should be 7 Ft. Lbs with a dry cork or synthetic gasket but if you use sealants with or without the gasket then you need to employ the 'squish' method. In this case you apply the gasket and tighten the bolts until you see the gasket and/or sealant begin to ooze out from the gap. This is often an intuitive thing as the various combinations of gaskets or sealants will act differently.

On AMC V-8s I prefer to use a cork gasket along with a thin layer of RTV and tighten until I see the RTV begin to ooze out between the pan and block. The longer you allow the RTV to set up the better the squish factor.

Also, when you install the rear main seal, instead of aligning the ends of the seal with the block/cap, rotate it a bit farther until a 1/4" to 5/16" of one end is protruding. This removes the seal ends from the cap/block joint and adds additional sealing.

1977 Cherokee Chief - The Blair Jeep Project III

A collection of parts flying in close formation

A collection of parts flying in close formation

-

Tatsadasayago

- Posts: 3684

- Joined: Thu Aug 28, 2014 2:22 pm

- Location: Sacramento, CA

Re: Torque specs on the oil pan and rod/main bearing caps ?

I'll add that since AMC engines tend to be leakers, so I'll often employ a cork gasket with RTV and after the sealant begins to 'skin', I'll torque the bolts to about half the required amount and go to bed. The next day I'll finish the torquing since the RTV has had overnight to firm up. This method assures a tight seal between the two surfaces.

The Blair III is a good example. In the 7 years since I sealed up her engine there is not a single leak. It took patience and planning but yeah, you can keep a Rambler from puking all over the driveway.

The Blair III is a good example. In the 7 years since I sealed up her engine there is not a single leak. It took patience and planning but yeah, you can keep a Rambler from puking all over the driveway.

1977 Cherokee Chief - The Blair Jeep Project III

A collection of parts flying in close formation

A collection of parts flying in close formation

-

candymancan

Topic author - Posts: 3684

- Joined: Tue Mar 22, 2016 11:32 pm

Re: Torque specs on the oil pan and rod/main bearing caps ?

Well i use the right stuff expensive, over normal rtv but can be filled and driven right after. I ll just used RTV over gaskets. I hate gaskets because if something is bent or scratched or whatever it always leaks ! lol.

What do you mean about the rear main ? by rotating it, im a tad confused ? I though the seal just pushes in, maybe have to use a punch and a light tap with a hammer to get it in at least thats what ive seen on vids, also heard of people use soap ? mm isnt soap bad for engines . Also the felpro rear main intructions say to use a file on the cap to smooth it out i assume so it doesnt rip the seal ? Have you heard of this b4 ?

What do you mean by dry torque ? obviously im putting some oil on the bearings before i put the caps for the rod and main bearing back on. Will this affect the torque spec ?

I just hope i can get the oil pan off and do all this without removing the exhaust.. I do not wanna break the studs on the y pipe off, i know they will break the second i try to unbolt em

What do you mean about the rear main ? by rotating it, im a tad confused ? I though the seal just pushes in, maybe have to use a punch and a light tap with a hammer to get it in at least thats what ive seen on vids, also heard of people use soap ? mm isnt soap bad for engines . Also the felpro rear main intructions say to use a file on the cap to smooth it out i assume so it doesnt rip the seal ? Have you heard of this b4 ?

What do you mean by dry torque ? obviously im putting some oil on the bearings before i put the caps for the rod and main bearing back on. Will this affect the torque spec ?

I just hope i can get the oil pan off and do all this without removing the exhaust.. I do not wanna break the studs on the y pipe off, i know they will break the second i try to unbolt em

1998 Jeep Grand Cherokee 5.9L Limited 219k

1998 Jeep Grand Cherokee 4.0 I6 laredo 430k

1990 Jeep Grand Wagoneer 155k

1976 Jeep J10.. 85k(repaired)

1998 Jeep Grand Cherokee 4.0 I6 laredo 430k

1990 Jeep Grand Wagoneer 155k

1976 Jeep J10.. 85k(repaired)

-

tgreese

- Posts: 7195

- Joined: Fri Jun 08, 2012 6:31 am

- Location: Medford MA USA

Re: Torque specs on the oil pan and rod/main bearing caps ?

It's nice of Tatsadasayago to tell you the torque settings, but they are listed in a table at the end of the V8 engine chapter in the FSM/TSM, along with the engine specifications. All you need to do is turn to the page and read.

Tim Reese

Maine beekeeper's truck: '77 J10 LWB, 258/T15/D20/3.54 bone stock, low options (delete radio), PS/PDB, hubcaps.

Browless and proud: '82 J20 360/T18/NP208/3.73, Destination A/Ts, 7600 GVWR

Copper Polly: '75 CJ-6, 304/T15, PS, BFG KM2s, soft top

GTI without the badges: '95 VW Golf Sport 2000cc 2D

Dual Everything: '15 Chryco Jeep Cherokee KL Trailhawk, ECO Green

Blockchain the vote.

Maine beekeeper's truck: '77 J10 LWB, 258/T15/D20/3.54 bone stock, low options (delete radio), PS/PDB, hubcaps.

Browless and proud: '82 J20 360/T18/NP208/3.73, Destination A/Ts, 7600 GVWR

Copper Polly: '75 CJ-6, 304/T15, PS, BFG KM2s, soft top

GTI without the badges: '95 VW Golf Sport 2000cc 2D

Dual Everything: '15 Chryco Jeep Cherokee KL Trailhawk, ECO Green

Blockchain the vote.

-

letank

- Posts: 4030

- Joined: Wed Oct 03, 2012 9:16 pm

- Location: SF bay area

Re: Torque specs on the oil pan and rod/main bearing caps ?

Don't forget to recheck torque on oil pan after a few driving cycles... or may be a month... in the 9 to 13lbs... mine were totally loose after a year.

Michel

74 wag (349 Kmiles... parked, next step is a rust free body)

85 Gwag (229 Kmiles... the running test lab)

74 wag (349 Kmiles... parked, next step is a rust free body)

85 Gwag (229 Kmiles... the running test lab)

-

Stuka

- Site Admin

- Posts: 11812

- Joined: Thu May 12, 2011 5:53 pm

- Location: CA

- Contact:

Re: Torque specs on the oil pan and rod/main bearing caps ?

They are, but not everybody has one, and nice info to have search able on the forum.tgreese wrote:It's nice of Tatsadasayago to tell you the torque settings, but they are listed in a table at the end of the V8 engine chapter in the FSM/TSM, along with the engine specifications. All you need to do is turn to the page and read.

2017 JKU Rubicon

Pevious Jeeps: 1981 J10, 1975 Cherokee, 2008 JK, 2005 KJ, 1989 XJ

Pevious Jeeps: 1981 J10, 1975 Cherokee, 2008 JK, 2005 KJ, 1989 XJ

-

Tatsadasayago

- Posts: 3684

- Joined: Thu Aug 28, 2014 2:22 pm

- Location: Sacramento, CA

Re: Torque specs on the oil pan and rod/main bearing caps ?

The reason for allowing the RTV to 'skin' or cure for a bit is to create a compressible gasket. If you simply run a bead then tighten the bolts down you are forcing the soft silicone away from the surfaces.candymancan wrote:Well i use the right stuff expensive, over normal rtv but can be filled and driven right after. I ll just used RTV over gaskets. I hate gaskets because if something is bent or scratched or whatever it always leaks ! lol.

What do you mean about the rear main ? by rotating it, im a tad confused ? I though the seal just pushes in, maybe have to use a punch and a light tap with a hammer to get it in at least thats what ive seen on vids, also heard of people use soap ? mm isnt soap bad for engines . Also the felpro rear main intructions say to use a file on the cap to smooth it out i assume so it doesnt rip the seal ? Have you heard of this b4 ?

What do you mean by dry torque ? obviously im putting some oil on the bearings before i put the caps for the rod and main bearing back on. Will this affect the torque spec ?

I just hope i can get the oil pan off and do all this without removing the exhaust.. I do not wanna break the studs on the y pipe off, i know they will break the second i try to unbolt em

{EDIT} What I described is an old fashioned method for achieving a compressible gasket. Modern engines usually employ this sealing technique by using a pre-formed rubber gasket that compresses under pressure and expands to create a seal between two surfaces.

Running a bead of sealant between two machined surfaces then tightening things down works because there is often no significant gap between them. A stamped steel valve cover or oil pan, especially if it has been removed previously, won't likely have a flat gasket surface since most people don't take the time to peen the holes and straighten the lip.

By rotating the rear main seal, I mean installing it as usual then pushing one end into the block about 1/4" while the other end protrudes into the main cap. The reasoning behind this is if the seal ends aren't lined up with the cap/block mating surface you have some additional insurance against a leak where the ends meet. Of course, one could add a small dab of RTV to the ends and achieve a similar result.

It's always a good idea to de-burr the main and rod cap surfaces; even if it nothing more than running the cap across some medium grit sandpaper. Back in the day this was part of the process known as Blueprinting an engine, but is becoming something of a lost art outside of professional engine building circles.

Dry torque refers to the bolt or nut tightened down without oil or other lubricant on the threads.

Good Luck!

1977 Cherokee Chief - The Blair Jeep Project III

A collection of parts flying in close formation

A collection of parts flying in close formation

-

tgreese

- Posts: 7195

- Joined: Fri Jun 08, 2012 6:31 am

- Location: Medford MA USA

Re: Torque specs on the oil pan and rod/main bearing caps ?

$22.99 on CD-ROM from RockAuto. Not much of a barrier to entry ...Stuka wrote:They are, bot not everybody has one, and nice info to have search able on the forum.tgreese wrote:It's nice of Tatsadasayago to tell you the torque settings, but they are listed in a table at the end of the V8 engine chapter in the FSM/TSM, along with the engine specifications. All you need to do is turn to the page and read.

http://www.rockauto.com/en/moreinfo.php ... 83&jsn=365

The TSM will help you a lot. More information in a focused format, specific to the owner's year and model. Essential.

Tim Reese

Maine beekeeper's truck: '77 J10 LWB, 258/T15/D20/3.54 bone stock, low options (delete radio), PS/PDB, hubcaps.

Browless and proud: '82 J20 360/T18/NP208/3.73, Destination A/Ts, 7600 GVWR

Copper Polly: '75 CJ-6, 304/T15, PS, BFG KM2s, soft top

GTI without the badges: '95 VW Golf Sport 2000cc 2D

Dual Everything: '15 Chryco Jeep Cherokee KL Trailhawk, ECO Green

Blockchain the vote.

Maine beekeeper's truck: '77 J10 LWB, 258/T15/D20/3.54 bone stock, low options (delete radio), PS/PDB, hubcaps.

Browless and proud: '82 J20 360/T18/NP208/3.73, Destination A/Ts, 7600 GVWR

Copper Polly: '75 CJ-6, 304/T15, PS, BFG KM2s, soft top

GTI without the badges: '95 VW Golf Sport 2000cc 2D

Dual Everything: '15 Chryco Jeep Cherokee KL Trailhawk, ECO Green

Blockchain the vote.

-

candymancan

Topic author - Posts: 3684

- Joined: Tue Mar 22, 2016 11:32 pm

Re: Torque specs on the oil pan and rod/main bearing caps ?

Tatsadasayago wrote:The reason for allowing the RTV to 'skin' or cure for a bit is to create a compressible gasket. If you simply run a bead then tighten the bolts down you are forcing the soft silicone away from the surfaces.candymancan wrote:Well i use the right stuff expensive, over normal rtv but can be filled and driven right after. I ll just used RTV over gaskets. I hate gaskets because if something is bent or scratched or whatever it always leaks ! lol.

What do you mean about the rear main ? by rotating it, im a tad confused ? I though the seal just pushes in, maybe have to use a punch and a light tap with a hammer to get it in at least thats what ive seen on vids, also heard of people use soap ? mm isnt soap bad for engines . Also the felpro rear main intructions say to use a file on the cap to smooth it out i assume so it doesnt rip the seal ? Have you heard of this b4 ?

What do you mean by dry torque ? obviously im putting some oil on the bearings before i put the caps for the rod and main bearing back on. Will this affect the torque spec ?

I just hope i can get the oil pan off and do all this without removing the exhaust.. I do not wanna break the studs on the y pipe off, i know they will break the second i try to unbolt em

{EDIT} What I described is an old fashioned method for achieving a compressible gasket. Modern engines usually employ this sealing technique by using a pre-formed rubber gasket that compresses under pressure and expands to create a seal between two surfaces.

Running a bead of sealant between two machined surfaces then tightening things down works because there is often no significant gap between them. A stamped steel valve cover or oil pan, especially if it has been removed previously, won't likely have a flat gasket surface since most people don't take the time to peen the holes and straighten the lip.

By rotating the rear main seal, I mean installing it as usual then pushing one end into the block about 1/4" while the other end protrudes into the main cap. The reasoning behind this is if the seal ends aren't lined up with the cap/block mating surface you have some additional insurance against a leak where the ends meet. Of course, one could add a small dab of RTV to the ends and achieve a similar result.

It's always a good idea to de-burr the main and rod cap surfaces; even if it nothing more than running the cap across some medium grit sandpaper. Back in the day this was part of the process known as Blueprinting an engine, but is becoming something of a lost art outside of professional engine building circles.

Dry torque refers to the bolt or nut tightened down without oil or other lubricant on the threads.

Good Luck!

Thanks a lot !!

I have a set of files. Which type do you recomend for the cap and on the engine ? Deburring you mean to remove any sharp edges and the whole U shaped lips to as not to cut the seal right ? I got my standard bearing today.. and can you believe this teamgrandwagoneer packed the two half bearings stacked on top of eachothed in a ziplock bag. Thr bearings were stuck on top of eachother and all scratched on the tin coating... smh... i called em and she placed an order for me directly from omnix, should get here sat.. but who does that ? Packs soft bearings on top of eachother with no cardboard or padding between em

On a side note im ordering my new leaf springs yomorrow. Do you know the ubolt sizes for the 7 pack front leaf springs ? If it means anything the spring packs are 1-15.16 in size. Im getting the stiffer 1450lbs springs vs the 1335lbs ones.

1998 Jeep Grand Cherokee 5.9L Limited 219k

1998 Jeep Grand Cherokee 4.0 I6 laredo 430k

1990 Jeep Grand Wagoneer 155k

1976 Jeep J10.. 85k(repaired)

1998 Jeep Grand Cherokee 4.0 I6 laredo 430k

1990 Jeep Grand Wagoneer 155k

1976 Jeep J10.. 85k(repaired)

-

Tatsadasayago

- Posts: 3684

- Joined: Thu Aug 28, 2014 2:22 pm

- Location: Sacramento, CA

Re: Torque specs on the oil pan and rod/main bearing caps ?

Ziplock bags? Syrysly?

The Babbitt top layer is there as a sacrificial media so the bearings can seat properly. I am kinda shocked that TGW would ship the bearings in that manner. Sounds like they are circling the drain.

The Babbitt top layer is there as a sacrificial media so the bearings can seat properly. I am kinda shocked that TGW would ship the bearings in that manner. Sounds like they are circling the drain.

1977 Cherokee Chief - The Blair Jeep Project III

A collection of parts flying in close formation

A collection of parts flying in close formation

-

tgreese

- Posts: 7195

- Joined: Fri Jun 08, 2012 6:31 am

- Location: Medford MA USA

Re: Torque specs on the oil pan and rod/main bearing caps ?

To me, their more serious offense is that they are sourcing engine bearings through Omix-Ada. That company has a reputation for selling some good stuff, some things you can get nowhere else, and quite a lot of junk. I guarantee that Omix does not make these bearings - they are instead buying full sets at wholesale and selling individual bearings. I suspect it's Omix that's throwing a couple of bearings in a zip lock bag and drop-shipping them to you. TGW is just the enabler, taking their cut. Omix does the drop-ship thing a lot ... the retailer never sees the part, and just places the order with Omix. Drop-ship charges from Omix are really expensive, and only depend on the dollar value of the order, not the actual shipping charges. Tastes like scam.

You can get these bearings from RockAuto or your local auto parts store easily. RockAuto shows both Mahle/Clevite brand and Sealed Power ... including the 1 and 2 thou undersized bearings.

http://www.rockauto.com/en/moreinfo.php ... 83&jsn=424

http://www.rockauto.com/en/moreinfo.php ... 83&jsn=423

You can get these bearings from RockAuto or your local auto parts store easily. RockAuto shows both Mahle/Clevite brand and Sealed Power ... including the 1 and 2 thou undersized bearings.

http://www.rockauto.com/en/moreinfo.php ... 83&jsn=424

http://www.rockauto.com/en/moreinfo.php ... 83&jsn=423

Tim Reese

Maine beekeeper's truck: '77 J10 LWB, 258/T15/D20/3.54 bone stock, low options (delete radio), PS/PDB, hubcaps.

Browless and proud: '82 J20 360/T18/NP208/3.73, Destination A/Ts, 7600 GVWR

Copper Polly: '75 CJ-6, 304/T15, PS, BFG KM2s, soft top

GTI without the badges: '95 VW Golf Sport 2000cc 2D

Dual Everything: '15 Chryco Jeep Cherokee KL Trailhawk, ECO Green

Blockchain the vote.

Maine beekeeper's truck: '77 J10 LWB, 258/T15/D20/3.54 bone stock, low options (delete radio), PS/PDB, hubcaps.

Browless and proud: '82 J20 360/T18/NP208/3.73, Destination A/Ts, 7600 GVWR

Copper Polly: '75 CJ-6, 304/T15, PS, BFG KM2s, soft top

GTI without the badges: '95 VW Golf Sport 2000cc 2D

Dual Everything: '15 Chryco Jeep Cherokee KL Trailhawk, ECO Green

Blockchain the vote.

-

candymancan

Topic author - Posts: 3684

- Joined: Tue Mar 22, 2016 11:32 pm

Re: Torque specs on the oil pan and rod/main bearing caps ?

No i got the bearings today from omix and they were packed nicely in a box and ina smaller box and sealed., but they are friggin made in china vs the clevite made in america bearing i originally ordered from TGW... Im frigging pissed how hard it is to get proper bearings.. I ordered bearings 16 days ago and im still in the ying yang from 3 companies.

I also ordered some from BJoff-road 6 days ago and they still havent mailed em out. Ryan emailed asking if im sure i wanted 1 bearing after day 2 and im like dude.. I ordered 1 bearing why are you wasting my time by not shipping it out because you arent sure if i wanted 1 bearing.. They have a page that specifies 1 clevite bearing for an AMC304/360.

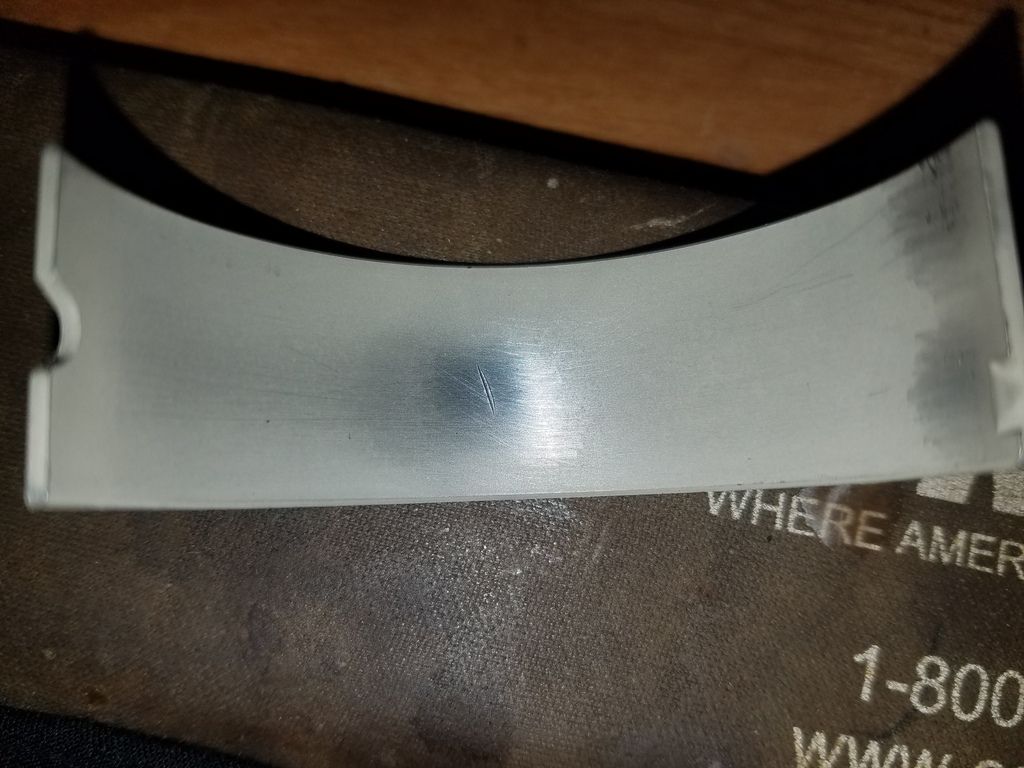

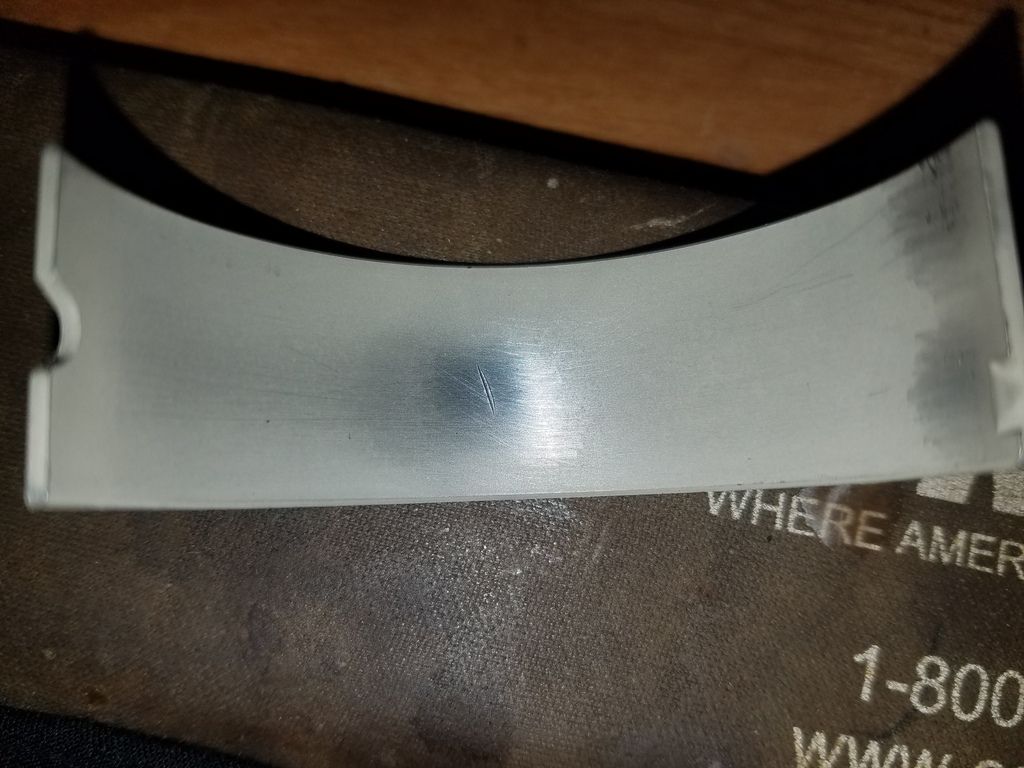

Here are the bearing pics of what i have so far. Im debating on just rolling with the one from TGW they originally sent me, but im not sure if this deep scratch will hurt my crank ? I used my finger nail to get the ridges down so now its flat but still. And then the stuff Omix sent me.. this made in china bearing... looking at the tin coatings between the clevit standard and this omix standard bearing.. the chinese one looks thinner to me or am i just imagining this ?? Also the chinese one on the side where the U cut on the bearing is looks kinda butchered compared to the clevite one.

I dunno, which one would you guys use ? Or should i not use either of em ?

First two pics is the chinese Omix bearing i got today.. That U shape what is that for, and does it look butchered to you ? like its missing alot of the tin on the bottom of the u shape. The third pic is the omix and TGW clevite bearing, left is the omix and right is the clevite. Am i imagining this or is the chinese one thinner on the tin coating ? The TGW one on the right feels heavier too

I also ordered some from BJoff-road 6 days ago and they still havent mailed em out. Ryan emailed asking if im sure i wanted 1 bearing after day 2 and im like dude.. I ordered 1 bearing why are you wasting my time by not shipping it out because you arent sure if i wanted 1 bearing.. They have a page that specifies 1 clevite bearing for an AMC304/360.

Here are the bearing pics of what i have so far. Im debating on just rolling with the one from TGW they originally sent me, but im not sure if this deep scratch will hurt my crank ? I used my finger nail to get the ridges down so now its flat but still. And then the stuff Omix sent me.. this made in china bearing... looking at the tin coatings between the clevit standard and this omix standard bearing.. the chinese one looks thinner to me or am i just imagining this ?? Also the chinese one on the side where the U cut on the bearing is looks kinda butchered compared to the clevite one.

I dunno, which one would you guys use ? Or should i not use either of em ?

First two pics is the chinese Omix bearing i got today.. That U shape what is that for, and does it look butchered to you ? like its missing alot of the tin on the bottom of the u shape. The third pic is the omix and TGW clevite bearing, left is the omix and right is the clevite. Am i imagining this or is the chinese one thinner on the tin coating ? The TGW one on the right feels heavier too

1998 Jeep Grand Cherokee 5.9L Limited 219k

1998 Jeep Grand Cherokee 4.0 I6 laredo 430k

1990 Jeep Grand Wagoneer 155k

1976 Jeep J10.. 85k(repaired)

1998 Jeep Grand Cherokee 4.0 I6 laredo 430k

1990 Jeep Grand Wagoneer 155k

1976 Jeep J10.. 85k(repaired)

-

Tatsadasayago

- Posts: 3684

- Joined: Thu Aug 28, 2014 2:22 pm

- Location: Sacramento, CA

Re: Torque specs on the oil pan and rod/main bearing caps ?

The oval cutout is a chamfer to eliminate a sharp edge where the bearing and crank meet. It is commonly done to the rod and main journals rather than the bearings, but some foreign made bearings have this as a matter of routine.

While I wouldn't run that scratched bearing, but in reality it's going to look a whole lot worse after just a few revolutions as it seats with the grooves on your crank...but I'd go with a Clevite or TRW before some no-name bearing from an unknown source.

I would submit that the most important thing here is bearing clearances. It is critical that you measure the crank journal to confirm it's actual diameter. There were many engines that came from the factory with oversize camshaft bearing bores, undersize rod and main journals and even oversized cylinder bores and you can identify if yours is one of them without tearing the oil pan off.

Check the engine ID tag on the front of the passenger side valve cover.

P-One or more undersize rod bearing journals -.010"

M-All crankshaft journals undersize -.010"

PM-All crank and rod journals -.010"

B-All cylinder bores +.010"

C-All cam bearing bores +.010"

This shouldn't be taken as a matter of fact because many engines didn't get the markings and there is no telling if the valve cover came off another engine. Lastly, the engine could have been rebuilt over the years and the crank could already be at -.020" undersize.

This is why measuring is the only way to know for sure. You can cheat a bit by using plastigauge to measure the installed clearance easy enough.

Good Luck

While I wouldn't run that scratched bearing, but in reality it's going to look a whole lot worse after just a few revolutions as it seats with the grooves on your crank...but I'd go with a Clevite or TRW before some no-name bearing from an unknown source.

I would submit that the most important thing here is bearing clearances. It is critical that you measure the crank journal to confirm it's actual diameter. There were many engines that came from the factory with oversize camshaft bearing bores, undersize rod and main journals and even oversized cylinder bores and you can identify if yours is one of them without tearing the oil pan off.

Check the engine ID tag on the front of the passenger side valve cover.

P-One or more undersize rod bearing journals -.010"

M-All crankshaft journals undersize -.010"

PM-All crank and rod journals -.010"

B-All cylinder bores +.010"

C-All cam bearing bores +.010"

This shouldn't be taken as a matter of fact because many engines didn't get the markings and there is no telling if the valve cover came off another engine. Lastly, the engine could have been rebuilt over the years and the crank could already be at -.020" undersize.

This is why measuring is the only way to know for sure. You can cheat a bit by using plastigauge to measure the installed clearance easy enough.

Good Luck

1977 Cherokee Chief - The Blair Jeep Project III

A collection of parts flying in close formation

A collection of parts flying in close formation

-

candymancan

Topic author - Posts: 3684

- Joined: Tue Mar 22, 2016 11:32 pm

Re: Torque specs on the oil pan and rod/main bearing caps ?

man, chrysler sucks.. my oil pan is slightly different then the 87s oil pan.. holy crap man i spent like 2 hours trying to get my new pan on and the new pan seems bigger.. It wouldnt fit and then i realized my pan had dents in it to keep away from the Y pipe and stuff.. Pisses me of !! So i couldnt get my pan on and finish the job.. i had to put the old rusty one on temp with a few bolts on it to keep the bottom of the engine away from the moisture outside because it might rain. Why would they change pans through the years ? holding em side by side they look nothing alike actually

Also i couldnt tap the upper rear main seal out.. it wouldnt come out. and the exhaust Y pipe was mainly in the way as well.. The seal is like stuck in there.. i could only get the lower seal out which turned into plastic because the rubber was dry.. This really pisses me off. hopefully it doesnt leak with only half a new seal.. Been working on this for 6 hours now so iritating !!!!! The oil pickup tube was covered halfway by the pan gasket that turned into hard plastic over the years so i cleaned that up

The oil pickup tube was covered halfway by the pan gasket that turned into hard plastic over the years so i cleaned that up

Anyway i took off the rod caps of 7 and 8, the journal looks really good i think, i couldnt feel anything with my fingernail except one little scratch on journal 8 but it wasnt that bad tbh. And the bearings on the caps looked brand new still so i didnt even touch em i just put the caps back on. They looked exactly like my clevite bearing minus the deep scratch in it they arent even worn at all. Litterally they look cloudy still not shiny at all. I forgot to take a picture of them but i took pics of the journals. The main bearing looked good as well and the journal wasnt scratched at all. Also the cylinders were honed still as i rotated the engine. Cylinder 8 though has a few scratches on the wall.

So where is my knocking coming from ??? The flex plate looked good too, could my knocking then be piston slap in cylinder 8 or a wrist pin ?

Also i couldnt tap the upper rear main seal out.. it wouldnt come out. and the exhaust Y pipe was mainly in the way as well.. The seal is like stuck in there.. i could only get the lower seal out which turned into plastic because the rubber was dry.. This really pisses me off. hopefully it doesnt leak with only half a new seal.. Been working on this for 6 hours now so iritating !!!!!

Anyway i took off the rod caps of 7 and 8, the journal looks really good i think, i couldnt feel anything with my fingernail except one little scratch on journal 8 but it wasnt that bad tbh. And the bearings on the caps looked brand new still so i didnt even touch em i just put the caps back on. They looked exactly like my clevite bearing minus the deep scratch in it they arent even worn at all. Litterally they look cloudy still not shiny at all. I forgot to take a picture of them but i took pics of the journals. The main bearing looked good as well and the journal wasnt scratched at all. Also the cylinders were honed still as i rotated the engine. Cylinder 8 though has a few scratches on the wall.

So where is my knocking coming from ??? The flex plate looked good too, could my knocking then be piston slap in cylinder 8 or a wrist pin ?

1998 Jeep Grand Cherokee 5.9L Limited 219k

1998 Jeep Grand Cherokee 4.0 I6 laredo 430k

1990 Jeep Grand Wagoneer 155k

1976 Jeep J10.. 85k(repaired)

1998 Jeep Grand Cherokee 4.0 I6 laredo 430k

1990 Jeep Grand Wagoneer 155k

1976 Jeep J10.. 85k(repaired)

-

Tatsadasayago

- Posts: 3684

- Joined: Thu Aug 28, 2014 2:22 pm

- Location: Sacramento, CA

Re: Torque specs on the oil pan and rod/main bearing caps ?

A scratch line parallel with the bore indicates either a broken ring or piston...

Could very well be a broken skirt. Did you see any chucks of aluminum or cast iron in the pan after you pulled it?

Could very well be a broken skirt. Did you see any chucks of aluminum or cast iron in the pan after you pulled it?

1977 Cherokee Chief - The Blair Jeep Project III

A collection of parts flying in close formation

A collection of parts flying in close formation

-

Tatsadasayago

- Posts: 3684

- Joined: Thu Aug 28, 2014 2:22 pm

- Location: Sacramento, CA

Re: Torque specs on the oil pan and rod/main bearing caps ?

Oh, and when you can't remove the upper rear main seal the trick is to loosen all the main caps so the crank moves down a bit...

1977 Cherokee Chief - The Blair Jeep Project III

A collection of parts flying in close formation

A collection of parts flying in close formation

-

candymancan

Topic author - Posts: 3684

- Joined: Tue Mar 22, 2016 11:32 pm

Re: Torque specs on the oil pan and rod/main bearing caps ?

Ok well ill try that tomorrow thrn since i havent reslly put ny pan back on. I had to put it on with 4 bolts becsuse it got dark 9pm out and i have no garage.

Hopfully that works because damn....

It had scratches going uo and down yes. Ill take pics of thr cam shaft lobs that can be seen anyway. And i did take pics of cylinder 8 scratchs. The piston looked fine. Wasnt cracked or missing chunks. The oil pan was spick and span clean. No sludge not one spec of metal

Hopfully that works because damn....

It had scratches going uo and down yes. Ill take pics of thr cam shaft lobs that can be seen anyway. And i did take pics of cylinder 8 scratchs. The piston looked fine. Wasnt cracked or missing chunks. The oil pan was spick and span clean. No sludge not one spec of metal

1998 Jeep Grand Cherokee 5.9L Limited 219k

1998 Jeep Grand Cherokee 4.0 I6 laredo 430k

1990 Jeep Grand Wagoneer 155k

1976 Jeep J10.. 85k(repaired)

1998 Jeep Grand Cherokee 4.0 I6 laredo 430k

1990 Jeep Grand Wagoneer 155k

1976 Jeep J10.. 85k(repaired)

-

candymancan

Topic author - Posts: 3684

- Joined: Tue Mar 22, 2016 11:32 pm

Re: Torque specs on the oil pan and rod/main bearing caps ?

Well finally got my pan on.. this fel pro cork 4 peice gasket sucks lol what a pain to put on... I think ima pay a shop to do my rear main seal if it still leaks. Because this was one of the toughest jobs ive ever done.

Ive done timing chains intake manifolds transfercases.. and dropping thr oil pan and finding out the 90-91 have specisl oil pans vs the 89 and older pissed me off.

And then manovering the pan between the exhaust and everything else was pitfa... and i still couldnt get the upper real main seal out... i gave up its too tight in there even by removing the crank bolts...

Cant even get a torque wrench in there to torque the pan bolts prioerly i had to go by what 7ft lbs felt like when i torqued a few of em... god damn.

I hope this doesnt leak because this was a pain

Ive done timing chains intake manifolds transfercases.. and dropping thr oil pan and finding out the 90-91 have specisl oil pans vs the 89 and older pissed me off.

And then manovering the pan between the exhaust and everything else was pitfa... and i still couldnt get the upper real main seal out... i gave up its too tight in there even by removing the crank bolts...

Cant even get a torque wrench in there to torque the pan bolts prioerly i had to go by what 7ft lbs felt like when i torqued a few of em... god damn.

I hope this doesnt leak because this was a pain

1998 Jeep Grand Cherokee 5.9L Limited 219k

1998 Jeep Grand Cherokee 4.0 I6 laredo 430k

1990 Jeep Grand Wagoneer 155k

1976 Jeep J10.. 85k(repaired)

1998 Jeep Grand Cherokee 4.0 I6 laredo 430k

1990 Jeep Grand Wagoneer 155k

1976 Jeep J10.. 85k(repaired)

-

tedlovesjeeps71

- Posts: 2905

- Joined: Fri Jul 22, 2016 4:39 pm

Re: Torque specs on the oil pan and rod/main bearing caps ?

RMS are never fun. It's a crappy job made worse by the conditions you're working in. Even on a lift and having let the motor drip dry for a couple days... it's always still and adventure.

The upper seal is the most frustrating *expletive* to do. Sometimes it comes out easy with a few taps of a soft drift punch. Sometimes even loosening all the mains and letting the crank relax is only a little help. It just sux anyway you cut it.

And then there is the ever present struggle of getting the new one in without peeling a chunk off it. It's like it's designed to be a PITA.

Good luck with yours working out. I just did the wife's and I'm only about 40% sure it won't leak.

Sent from my iPhone using Tapatalk

The upper seal is the most frustrating *expletive* to do. Sometimes it comes out easy with a few taps of a soft drift punch. Sometimes even loosening all the mains and letting the crank relax is only a little help. It just sux anyway you cut it.

And then there is the ever present struggle of getting the new one in without peeling a chunk off it. It's like it's designed to be a PITA.

Good luck with yours working out. I just did the wife's and I'm only about 40% sure it won't leak.

Sent from my iPhone using Tapatalk